문의 사항이 지연되는 것을 방지하려면 WhatsApp/WeChat/Skype를 메시지와 함께 입력해 주세요. 그러면 곧바로 연락을 드릴 수 있습니다.

24시간 이내에 회신해 드리겠습니다. 긴급한 경우 WhatsApp을 추가하세요: +8617888313102또는 WeChat: +86 17864107808. 또는 전화 +86 17864107808 곧장.

*저희는 귀하의 기밀을 존중하며 모든 정보는 보호됩니다. 저희는 귀하의 정보를 귀하의 문의에 답변하는 데만 사용하며, 요청하지 않은 이메일이나 홍보 메시지를 보내지 않습니다.

Published: 2026.01.07 | Updated: 2026.01.07 | Category: Industrial Manufacturing, Glass Technology

Finding the best UV printer for tempered glass and curved glass represents one of the most significant challenges in modern industrial printing. These specialized glass types present unique obstacles that standard UV 플랫베드 프린터 cannot adequately address. Tempered glass requires specific ink formulations and curing parameters, while curved surfaces demand advanced mechanical adaptations for consistent 고품질 인쇄.

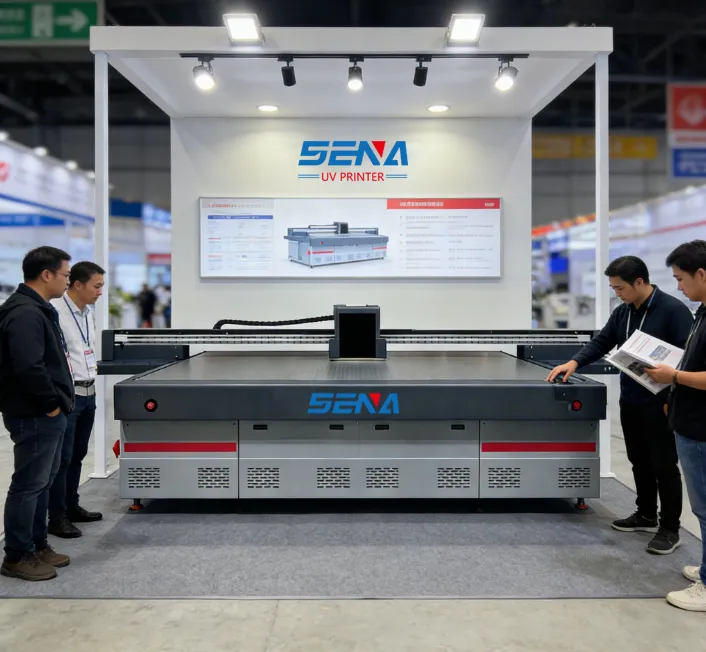

The newly launched SENA glass lithography machine series provides comprehensive solutions specifically engineered for these demanding applications. These industrial-grade UV 프린터 combine precision engineering with specialized features to handle both tempered (safety) glass 그리고 curved/bent glass surfaces with exceptional results.

Figure 1: Specialized SENA UV printer successfully printing on curved tempered glass surface

This comprehensive guide examines the technical requirements, available technologies, and specific solutions for printing on these challenging 기질. We’ll explore why standard flatbed printers for sale often fail with glass applications and what features are essential for success.

Tempered (or toughened) glass presents specific challenges that require specialized UV인쇄 solutions. Unlike regular glass, tempered glass cannot be cut or drilled after tempering, and its surface tension properties affect ink adhesion.

Printing MUST occur BEFORE glass tempering for most applications. The tempering process (heating to 620°C+ then rapid cooling) would destroy standard UV잉크 prints. However, some specialized inks can withstand post-tempering applications with proper curing.

그만큼 SENA glass lithography machine incorporates specialized features for tempered glass applications:

For 고품질 인쇄 on tempered glass, the printer must maintain consistent ink deposition despite the glass’s surface tension and potential minor warping from the tempering process.

Printing on curved or bent glass requires fundamentally different approaches than flat surface printing. The curvature creates varying distances between the printhead and glass surface, demanding advanced mechanical and software solutions.

Cylindrical or slightly curved glass (bending in one direction only). Requires automatic height adjustment or specialized curved fixtures.

Glass curved in multiple directions (domes, automotive windshields). Requires 3D profiling and advanced printhead articulation.

Architectural glass with slight bends. Can be handled with vacuum forming to temporary flat surface or specialized curved beds.

Figure 2: SENA UV printer with rotary attachment for curved glass bottle printing

그만큼 SENA UV flatbed printer series offers optional curved glass packages that include these specialized features, making them ideal for automotive glass, architectural curved panels, and decorative curved glass applications.

Successful glass printing requires more than just a standard 디지털 인쇄기. Specialized technologies must be integrated to handle glass’s unique properties.

| Technology Component | Standard UV Printer | SENA Glass Printing Solution |

|---|---|---|

| Printhead System | 2-4 standard printheads | 5-8 Ricoh industrial printheads for speed and quality |

| Height Control | Manual or basic auto adjustment | Precision automatic height adjustment with 0.01mm accuracy |

| Surface Detection | Basic proximity sensors | 선택 과목 CCD visual scanning system with 3D surface mapping |

| 경화 시스템 | Standard UV lamps | 조절할 수 있는 자외선 LED array with thermal monitoring |

| 유지 | Manual cleaning | Integrated automatic cleaning system for consistent performance |

| Special Features | Basic flat printing only | Rotary printing, curved fixtures, varnish printing 옵션 |

그만큼 Ricoh industrial printhead system (5-8 head configuration) offers specific advantages for glass printing:

SENA offers a range of specialized UV 프린터 specifically configured for tempered and curved glass applications. Each size is designed to meet the customer’s customized requirements for specific glass printing needs.

| 모델 | 인쇄 영역 | 가장 적합한 | Glass-Specific Features | 더 알아보기 |

|---|---|---|---|---|

| SN-9060 Glass Pro | 900×600mm | Small to medium tempered glass panels, decorative glass | 4-6 Ricoh heads, basic curved capability | View Details → |

| SN-Glass Lithography Pro | Up to 1600×1000mm | Tempered glass manufacturing, architectural glass | 5-8 Ricoh heads, full tempering compatibility | View Details → |

| SN-2513G Curved Glass Edition | 2500×1300mm | Large curved architectural glass, automotive glass | Curved bed option, 3D profiling, 6-8 Ricoh heads | View Details → |

All SENA glass lithography machines come with 1-year warranty 그리고 24/7 engineer online support, ensuring minimal downtime for production operations. Authoritative certificates verify compliance with international safety and performance standards.

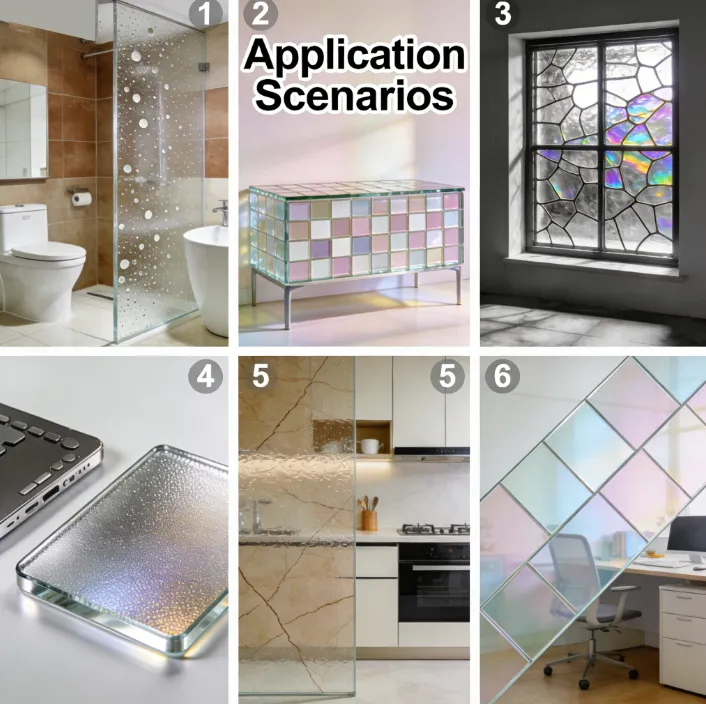

Glass printing is inherently diverse, with applications ranging from small decorative items to large architectural panels. SENA’s approach centers on one-to-one customization to ensure each UV 플랫베드 프린터 perfectly matches the customer’s specific requirements.

Our engineering team provides complete customization services to ensure your UV 프린터 perfectly matches your:

Whether you need a 소형 UV 플랫베드 프린터 for boutique glass decoration or an industrial system for architectural glass production, our customization services ensure optimal performance for your specific application.

Glass printing applications demand exceptional quality and durability. SENA’s solutions incorporate multiple quality assurance features to ensure long-lasting results.

Must withstand weather, UV exposure, temperature fluctuations, and cleaning cycles for 10+ years

Requires chemical resistance (washer fluid), temperature cycling (-30°C to +80°C), and vibration resistance

Needs scratch resistance, cleaning chemical tolerance, and color stability in interior environments

그만큼 SENA glass printing system includes comprehensive testing protocols to verify print durability meets or exceeds industry standards for each specific application.

선택 best UV printer for tempered and curved glass requires careful consideration of technical capabilities, customization options, and long-term support. Standard flatbed printers for sale often lack the specialized features needed for consistent, high-quality glass printing results.

The SENA glass lithography machine series provides comprehensive solutions specifically engineered for challenging glass applications. With features like 5-8 Ricoh printheads, optional CCD visual scanning, automatic cleaning systems, and extensive customization options, these machines deliver reliable performance for the most demanding glass printing requirements.

Contact our glass printing specialists today for a personalized consultation. We’ll help you select and customize the perfect UV 프린터 for your specific tempered and curved glass applications.

Whether you’re producing architectural tempered glass, curved automotive components, decorative glass items, or specialized glass products, SENA’s multifunctional UV flatbed printers provide the technology, support, and customization needed for success in today’s competitive glass printing market.