문의 사항이 지연되는 것을 방지하려면 WhatsApp/WeChat/Skype를 메시지와 함께 입력해 주세요. 그러면 곧바로 연락을 드릴 수 있습니다.

24시간 이내에 회신해 드리겠습니다. 긴급한 경우 WhatsApp을 추가하세요: +8617888313102또는 WeChat: +86 17864107808. 또는 전화 +86 17864107808 곧장.

*저희는 귀하의 기밀을 존중하며 모든 정보는 보호됩니다. 저희는 귀하의 정보를 귀하의 문의에 답변하는 데만 사용하며, 요청하지 않은 이메일이나 홍보 메시지를 보내지 않습니다.

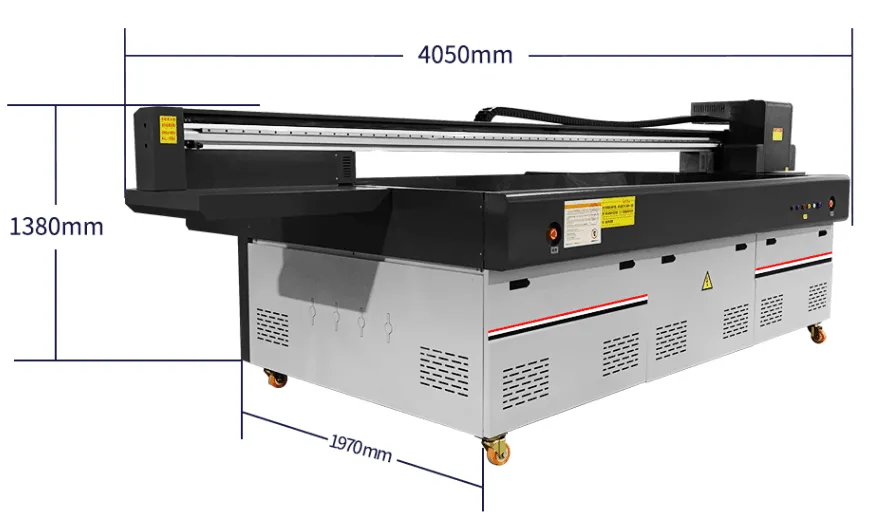

에이 UV glass lithography printer is a specialized type of UV 플랫베드 프린터 designed specifically for printing on glass surfaces using ultraviolet-curable inks. Unlike traditional printing methods that require screens or transfer films, this advanced 디지털 인쇄기 적용됩니다 UV잉크 directly onto glass substrates, which is instantly cured by 자외선 LED lamps to create durable, high-resolution designs.

The term “lithography” in this context refers to the precision printing capability that allows for detailed patterns, textures, and images to be applied directly to glass surfaces. Modern UV 잉크젯 프린터 have revolutionized glass decoration by enabling direct-to-glass printing with exceptional clarity and durability. The newly launched SENA UV flatbed printer series represents the latest advancement in this technology, offering unprecedented precision for glass printing applications.

Figure 1: A modern UV flatbed printer applying detailed patterns directly onto glass

에이 UV glass printer combines the precision of 잉크젯 프린터 technology with the durability of ultraviolet curing. The process involves:

자외선 LED lampsThe operation of a multifunctional UV flatbed printer for glass involves several sophisticated technological components working in harmony to deliver 고품질 인쇄 결과.

자외선 LED lamps emit ultraviolet light that instantly polymerizes the ink, creating a solid, durable layer that bonds directly with the glass.automatic lifting platform with precision height adjustment ensures optimal print distance for different glass thicknesses, from thin window panes to thick architectural glass.CCD visual scanning system ensures perfect registration on pre-cut or shaped glass pieces.Critical Components of a Professional UV Glass Printer:

CCD visual scanning system for alignmentautomatic cleaning system for maintenance

Figure 2: Precision printhead applying UV ink directly to glass surface

The latest generation of UV 프린터 incorporates advanced features that make glass printing more accessible, efficient, and profitable than ever before.

| 특징 | 설명 | Benefit for Glass Printing |

|---|---|---|

| CCD Visual Scanning | Optional camera system for perfect alignment | Enables precise printing on pre-cut or irregular glass shapes |

| Automatic Cleaning System | Automated printhead maintenance | Reduces downtime and ensures consistent print quality |

| Multiple Printhead Configuration | Customizable printhead setup | Increases printing speed and enables special color applications |

| Automatic Height Adjustment | Precise Z-axis control | Accommodates glass of varying thicknesses automatically |

| Rotary Attachment Option | Optional fixture for cylindrical objects | Enables printing on glass bottles, vases, and cylindrical containers |

| International Standard UV Ink | Certified, fade-resistant inks | Ensures long-lasting prints that resist fading and scratching |

The new SENA UV flatbed printer series offers:

CCD visual scanning system for precision alignmentautomatic cleaning system for reduced maintenanceAutomatic lifting platform for different glass thicknessesvarnish printing for protective coatings

Figure 3: UV lithography machine display

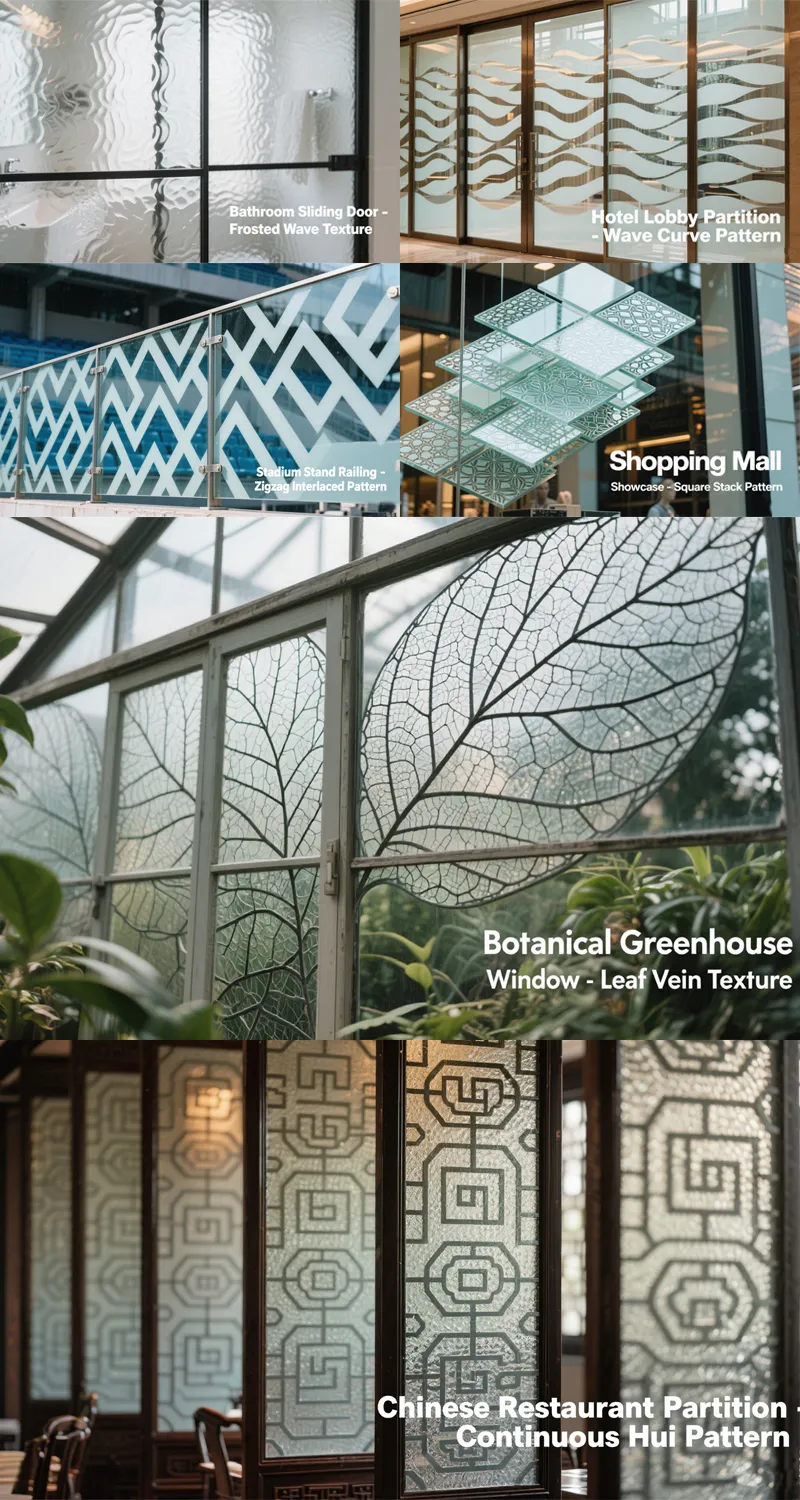

The versatility of modern flatbed printers for sale extends far beyond simple glass printing. These machines can handle a wide variety of glass types and applications.

A high-quality UV 플랫베드 프린터 can print on various glass surfaces including:

The same multifunctional UV flatbed printer that handles glass can also print on numerous other materials, making it a versatile investment:

SENA offers a comprehensive range of UV 플랫베드 프린터 designed to meet every glass printing requirement. Each size is tailored to meet the customer’s customized requirements, and our company provides comprehensive one-to-one customization 서비스.

Don’t miss the opportunity! Every SENA UV 프린터 can be customized with:

CCD visual scanning system, automatic cleaning system, 또는 multiple printheadsrotary printing fixtures for cylindrical glass objects| 모델 | 가장 적합한 | Max Glass Thickness | Special Features |

|---|---|---|---|

| SN-3045 | Small glass items, samples, prototypes | 100mm | Compact, cost-effective entry model |

| SN-9060 | Medium-sized glass panels, signage | 150mm | Balanced performance, optional CCD system |

| SN-1610 | Architectural glass, large panels | 200mm | High-speed, industrial production |

| SN-2513E | Extra large glass, mass production | 250mm | Maximum productivity, heavy-duty construction |

Investing in a professional UV glass lithography printer offers significant business advantages and excellent return on investment potential.

Why Choose SENA UV Printers:

automatic cleaning system reduce ongoing expenses자외선 LED curing uses less power than traditional systemsSENA provides comprehensive support for all UV 잉크젯 프린터:

Figure 4: UV lithography print machine case

The evolution of UV 플랫베드 인쇄 technology continues to advance, with new developments making glass printing more accessible and profitable than ever before.

The newly launched SENA UV Printer series represents the cutting edge of this technology, incorporating technology-leading features while maintaining easy operation 그리고 competitive pricing. With the ability to handle everything from small decorative glass items to large architectural panels, these multifunctional UV flatbed printers offer businesses a versatile solution for entering or expanding in the glass printing market.