문의 사항이 지연되는 것을 방지하려면 WhatsApp/WeChat/Skype를 메시지와 함께 입력해 주세요. 그러면 곧바로 연락을 드릴 수 있습니다.

24시간 이내에 회신해 드리겠습니다. 긴급한 경우 WhatsApp을 추가하세요: +8617888313102또는 WeChat: +86 17864107808. 또는 전화 +86 17864107808 곧장.

*저희는 귀하의 기밀을 존중하며 모든 정보는 보호됩니다. 저희는 귀하의 정보를 귀하의 문의에 답변하는 데만 사용하며, 요청하지 않은 이메일이나 홍보 메시지를 보내지 않습니다.

Published: Jan 14, 2026 | Updated: Jan 14, 2026 | Category: Industrial Manufacturing, Glass Technology

안 industrial glass lithography printer is a specialized type of UV 플랫베드 프린터 designed specifically for printing high-resolution patterns, images, and designs directly onto glass surfaces. Unlike traditional printing methods that require transfer media or chemical processes, these advanced 디지털 인쇄기 use ultraviolet (UV) light to instantly cure specially formulated UV잉크 directly on glass substrates.

These printers represent the pinnacle of modern 고품질 인쇄 technology for the glass industry, capable of handling both matte (frosted) and glossy glass surfaces with equal precision. The newly launched SENA UV Printer series embodies this technology, offering industrial-grade performance for architectural, decorative, and functional glass applications.

Figure 1: SENA industrial glass lithography printer processing large format architectural glass

Key characteristics of an industrial glass lithography printer 포함하다:

One of the most common questions about glass lithography printers is: “How thick of glass can it print on?” The answer depends on the specific model and configuration, but industrial-grade machines like the SENA series offer impressive thickness capabilities.

SENA industrial glass lithography printers can handle glass thickness ranging from:

3mm (0.12 inches) to 50mm (2 inches)

The standard configuration supports up to 25mm (1 inch) thick glass, with specialized configurations available for thicker materials up to 50mm for industrial applications.

| Glass Thickness | Typical Applications | Required Printer Features | SENA Model Recommendation |

|---|---|---|---|

| 3-6mm | Windows, picture frames, decorative panels | Standard height adjustment, vacuum table | SN-9060 |

| 6-12mm | Shower doors, interior partitions, furniture glass | Enhanced vacuum system, precise height control | SN-Glass Pro |

| 12-25mm | Architectural facades, security glass, display cases | Heavy-duty platform, industrial vacuum | SN-2513G |

| 25-50mm | Industrial components, specialized architectural | Custom configuration, reinforced structure | Custom Industrial Model |

그만큼 automatic lifting platform technology in SENA printers allows for precise adjustment to accommodate different glass thicknesses. This feature, combined with industrial-grade vacuum hold-down systems, ensures stable printing even on the thickest glass panels.

The technology behind glass lithography printers combines advanced 잉크젯 프린터 principles with specialized UV curing systems. Here’s how these multifunctional UV flatbed printers achieve exceptional results on glass:

Figure 2: UV LED curing process on textured glass surface

This combination of technologies enables SENA UV 프린터 전달하다 고품질 인쇄 results that meet the demanding standards of architectural and industrial glass applications.

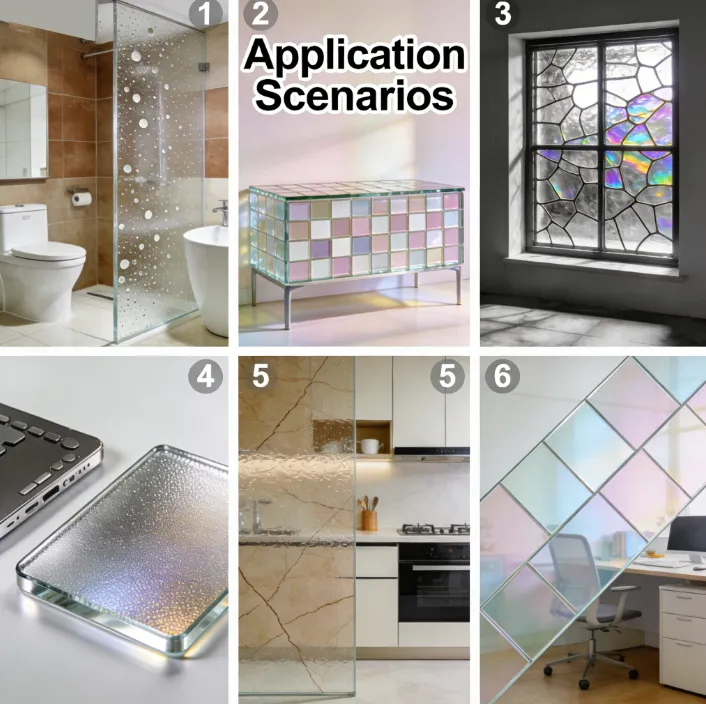

산업 glass lithography printers serve numerous sectors, with particular significance in architectural and interior design applications. The ability to print custom patterns directly onto glass has revolutionized these industries:

Building facades, curtain walls, office partitions, and structural glass elements with custom patterns or corporate branding

Custom designed bathroom doors, shower enclosures, and privacy glass with decorative patterns or company logos

Decorative windows for residential and commercial buildings, with integrated sun control patterns or artistic designs

Room dividers, glass walls, decorative panels, and furniture glass with custom artwork or geometric patterns

Storefronts, display cases, signage, and promotional glass elements with vibrant graphics and text

Laboratory glass, instrument panels, safety glass, and industrial components with functional markings

SENA glass lithography printers excel at printing on various glass surface finishes, including:

This versatility makes SENA printers ideal for flatbed printer for sale solutions serving multiple industries from a single equipment investment.

SENA’s approach to industrial glass lithography printers centers on customization and adaptability. We believe each size must meet the customer’s customized requirements, which is why we offer extensive configuration options.

Multiple sizes are customizable from compact to industrial scale. Our company provides one-to-one customization to match your specific production requirements.

Choose from various automation levels, printhead configurations, and specialized glass handling systems tailored to your application.

Pre-configured solutions for specific industries including architectural glass, bathroom door manufacturing, and window production.

Don’t miss this opportunity to configure your ideal glass printing solution. Our engineering team offers one-to-one customization for:

The newly launched SENA UV Printer series offers comprehensive solutions for every scale of glass printing operation. Each model is designed with specific applications and production volumes in mind.

인쇄 영역: 900×600mm

Max Glass Thickness: 25mm

Best For: Medium production, bathroom doors, windows

주요 특징: 6 Ricoh printheads, CCD vision option

View Specifications →

인쇄 영역: 1500×1000mm

Max Glass Thickness: 30mm

Best For: Architectural glass, large panels

주요 특징: 8 Ricoh printheads, full automation

View Specifications →

인쇄 영역: 2500×1300mm

Max Glass Thickness: 50mm (custom)

Best For: Building facades, industrial production

주요 특징: Heavy-duty construction, maximum productivity

View Specifications →

| 특징 | Standard Specification | Custom Options |

|---|---|---|

| 인쇄 해상도 | Up to 1200×1200 DPI | Variable resolution modes |

| 인쇄 속도 | Up to 150㎡/hour | High-speed configurations available |

| 잉크 시스템 | CMYK + White + Varnish | Special color configurations |

| Positioning Accuracy | ±0.1mm | Enhanced precision systems |

| Operating System | Windows-based control software | Custom workflow integration |

All SENA glass lithography printers feature factory-direct manufacturing, ensuring competitive pricing without compromising quality or performance.

Investing in industrial glass printing equipment requires comprehensive support infrastructure. SENA provides global solutions to ensure your success:

Our commitment extends beyond equipment delivery. We provide complete solutions including application testing, workflow optimization, and ongoing technical support to maximize your investment in glass lithography printing 기술.

산업 glass lithography printers represent a transformative technology for the glass manufacturing and architectural industries. By enabling direct, 고품질 인쇄 on glass surfaces up to 50mm thick, these advanced UV 플랫베드 프린터 open new possibilities for customization, decoration, and functional marking.

The SENA series of industrial glass lithography printers combines cutting-edge technology with practical customization options. With features like configurable 5-8 Ricoh printheads, optional CCD visual scanning, 그리고 automatic cleaning systems, these machines deliver reliable performance for the most demanding glass printing applications in bathroom door manufacturing, window production, and architectural glass fabrication.

Contact our glass printing specialists today for a personalized consultation. We’ll help you determine the ideal glass lithography printer configuration for your specific thickness requirements and application needs.

Whether you’re producing architectural glass panels, custom bathroom doors, decorative windows, or industrial glass components, SENA’s multifunctional UV flatbed printers provide the technology, support, and customization needed for success in today’s competitive glass manufacturing market.