문의 사항이 지연되는 것을 방지하려면 WhatsApp/WeChat/Skype를 메시지와 함께 입력해 주세요. 그러면 곧바로 연락을 드릴 수 있습니다.

24시간 이내에 회신해 드리겠습니다. 긴급한 경우 WhatsApp을 추가하세요: +86 17864107808또는 WeChat: +86 17864107808. 또는 전화 +86 17864107808 곧장.

*저희는 귀하의 기밀을 존중하며 모든 정보는 보호됩니다. 저희는 귀하의 정보를 귀하의 문의에 답변하는 데만 사용하며, 요청하지 않은 이메일이나 홍보 메시지를 보내지 않습니다.

Imagine being able to print vibrant, detailed images directly onto leather products with ease and precision. Thanks to UV flatbed printers, this is now a reality. In this article, we’ll explore how UV printing on leather is transforming the industry, making it possible to create custom leather items like never before. Discover why this cutting-edge technology is worth your attention and how it can benefit your business or creative projects.

UV printing on leather is a modern digital printing process that uses ultraviolet (UV) light to cure or dry ink as it is printed onto leather surfaces. This method allows for high-quality, durable prints on various types of leather materials, including genuine leather, faux leather, and PU leather.When the UV 프린터 적용합니다 UV잉크 onto the leather, the ink is immediately cured by the UV light, resulting in a fast and efficient printing process. This technology enables you to print directly onto leather, creating stunning leather products with intricate designs and vibrant colors.

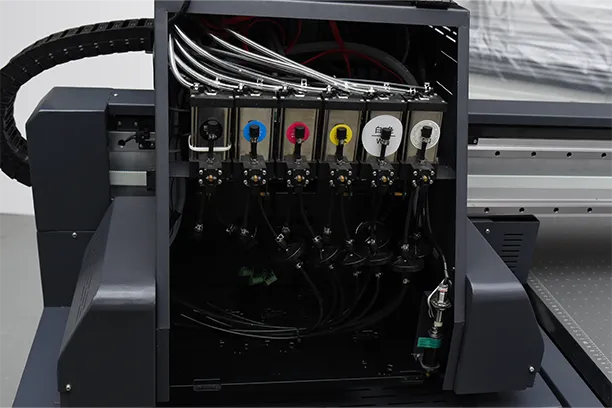

UV 플랫베드 프린터 are specialized 인쇄기 designed to handle a variety of materials, including leather. The “flatbed” refers to the flat surface on which the material is placed during printing. Here’s a simple breakdown of how these printers work:

This process results in sharp, vibrant images that are durable and resistant to fading.

There are several benefits to using UV printing on leather:

These advantages make UV printing an excellent choice for businesses looking to enhance their leather products.

UV 플랫베드 프린터 are capable of printing on a wide range of leather types, including:

Whether you’re working with real leather or artificial leather materials like PU leather, UV printers can handle the job effectively.

Selecting the appropriate leather printing machine is crucial for achieving the best results. Consider the following factors:

One example of a reliable printer is the SN-2513G 대형 UV 플랫베드 프린터, known for its generous printing heights and highly precise outputs.

UV잉크 is specially formulated to work with UV curing systems in printers. Its key characteristics include:

Using the right 잉크 is essential for high-quality digital printing on leather.

With UV printing technology, creating custom leather products has never been easier. Businesses and individuals can personalize items such as:

Personalized UV printing allows for unique designs, monograms, or branding directly on the leather items, adding value and appeal.

Printing directly onto leather involves several steps:

This printing process is straightforward and allows for high customization and efficiency.

To ensure optimal printing results on leather, keep these tips in mind:

Following these guidelines will help you maximize the capabilities of your UV leather printer.

UV flatbed printers have opened new horizons in the world of leather printing. From fashion accessories to personalized gifts, the ability to print directly onto leather offers endless possibilities. By understanding the technology and choosing the right equipment, you can elevate your leather products to new heights.주요 내용:

Ready to transform your leather products with UV printing technology? Explore our range of UV 플랫베드 프린터 and find the perfect printing solution for your needs.