Evite que sua consulta atrase a resposta, insira seu WhatsApp/WeChat/Skype junto com a mensagem, para que possamos contatá-lo o mais rápido possível

Responderemos em até 24 horas. Se for um caso urgente, adicione WhatsApp: +86 17864107808, ou WeChat: +86 17864107808. Ou ligue +86 17864107808 diretamente.

*Respeitamos sua confidencialidade e todas as informações são protegidas. Usaremos suas informações somente para responder à sua consulta e nunca enviaremos e-mails ou mensagens promocionais não solicitados.

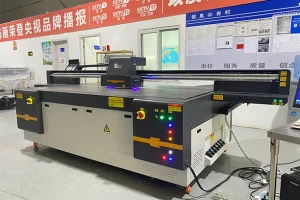

UV flatbed printer using the 3200 head usually has a high physical resolution and 3200 head can maintain a stable printing state, reduce the printhead problems caused by the print interruptions and defective products, reducing the maintenance costs and production risk of the equipment.

1.High Resolution Printing: The 3200 heads used by UV flatbed printers usually have higher physical resolution. For example, it can achieve a resolution range of 1200 – 2880 dots per inch (dpi). This means that very fine patterns and text can be printed, and some application scenarios that require high-precision printing, such as fine patterns on electronic product casings and tiny textures on jewelry boxes, can be clearly presented. For example, when printing complex animation patterns on mobile phone cases, the 3200 heads can vividly display the details in the pattern, such as the character’s hair, the highlights of the eyes, etc., adding higher added value to the product.

2.High-speed printing performance:3200 heads generally have a larger number of nozzles, which allows the nozzle to eject more ink droplets per unit time. Compared with printers with low number of nozzles, its printing speed is significantly improved. For example, when printing large-format advertising boards, such as 2m×3m PVC boards, it may take 30-40 minutes to complete the printing using ordinary nozzles, while the 3200 head can complete the same printing task in about 15-20 minutes, which is greatly Improved production efficiency. This can effectively shorten the production cycle and reduce costs for industries that mass-produce advertising materials, decorative panels and other products.

3.Strong Color Expression:3200 heads are generally able to achieve better color transitions and a richer color range. It can precisely control the size and spray position of ink droplets, making the mixing of colors more natural. For example, when printing landscape pictures, from the light blue of the sky to the turquoise of the distant mountains to the dark green of the nearby vegetation, the entire color gradient process can be very smooth and there will be no color discontinuity. Moreover, it can print more vivid and accurate colors, and can better restore the color effect of the original work for some industries that have strict color requirements, such as art reproduction and high-end packaging printing.

4.Good ink adaptability:This nozzle is compatible with multiple types of UV ink, including different color systems (such as CMYK, CMYK+W+V, etc.) and different ink characteristics (such as soft ink, Rigid ink, elastic ink, etc.). For example, when printing leather products, you can use soft ink so that the pattern can better adhere to the leather surface and will not crack when the leather is bent or folded; when printing hard plastic products, use hard ink It can ensure the wear resistance and scratch resistance of the pattern. This provides guarantee for high-quality printing on different materials and broadens the application scope of the printer.

5.High stability of the nozzle:During the design and manufacturing process of the 3200 head, advanced technology is usually used to ensure its stability. It has a good heat dissipation system and can work for a long time without overheating causing nozzle failure. At the same time, the internal structure of the nozzle is strong and the nozzle is not easily clogged. For example, in continuous printing operations, such as working 8-10 hours a day, the 3200 head can maintain a stable printing status, reduce printing interruptions and defective products caused by nozzle problems, and reduce equipment maintenance costs and production risks.