Чтобы избежать задержки ответа на ваш запрос, пожалуйста, укажите ваш WhatsApp/WeChat/Skype вместе с сообщением, чтобы мы могли связаться с вами в первый же момент.

Мы ответим вам в течение 24 часов. Если срочно, пожалуйста, добавьте WhatsApp: +8617888313102, или WeChat: +86 17864107808. Или позвоните +86 17864107808 напрямую.

*Мы уважаем вашу конфиденциальность, и вся информация защищена. Мы будем использовать вашу информацию только для ответа на ваш запрос и никогда не будем отправлять нежелательные электронные письма или рекламные сообщения.

Published: December 10, 2023 | Updated: December 10, 2023 | Category: Industrial Technology, Glass Manufacturing, Architectural Printing

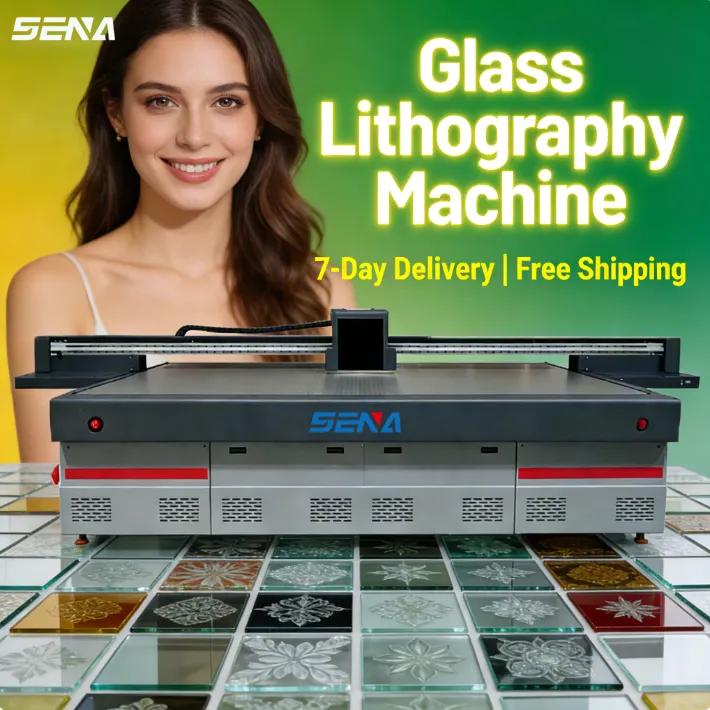

In architectural and commercial applications, the question of durability is paramount: How scratch-resistant are patterns printed on glass? Traditional glass decoration methods often compromise durability for aesthetics, but modern УФ планшетный принтер technology has revolutionized this balance. Today’s advanced glass lithography machines create patterns that withstand daily wear while maintaining exceptional visual quality.

The newly launched SENA UV flatbed printer series addresses this critical need for durability in architectural glass applications. These industrial-grade цифровые печатные машины использовать специализированные УФ-чернила formulations and precision engineering to create scratch-resistant patterns suitable for high-traffic environments like bathrooms, commercial spaces, and exterior applications.

Figure 1: SENA UV flatbed printer creating durable, scratch-resistant patterns on bathroom glass doors

This technology represents a significant advancement over traditional methods, offering both exceptional высококачественная печать and proven durability that meets the rigorous demands of commercial and residential applications.

The exceptional scratch resistance of patterns created by modern УФ-принтеры results from a combination of advanced materials and precise engineering processes:

SENA’s glass printing solutions have undergone rigorous testing with the following results:

The combination of these technologies ensures that patterns printed with SENA UV flatbed printers maintain their integrity and appearance even in demanding environments like commercial bathrooms, restaurant kitchens, and high-traffic public spaces.

To achieve consistent scratch-resistant results, SENA’s glass lithography machine incorporates specialized features designed for durability and precision:

Configurable with 5-8 Ricoh industrial printheads for optimal ink coverage and layer consistency essential for durable prints

Необязательный CCD visual scanning system ensures perfect registration for multi-layer protective coatings

Integrated automatic cleaning system maintains printhead performance for consistent ink deposition

Automatic lifting platform with vacuum hold-down ensures stable glass positioning during precise printing

Figure 2: Multi-layer UV ink application creating scratch-resistant patterns on glass surfaces

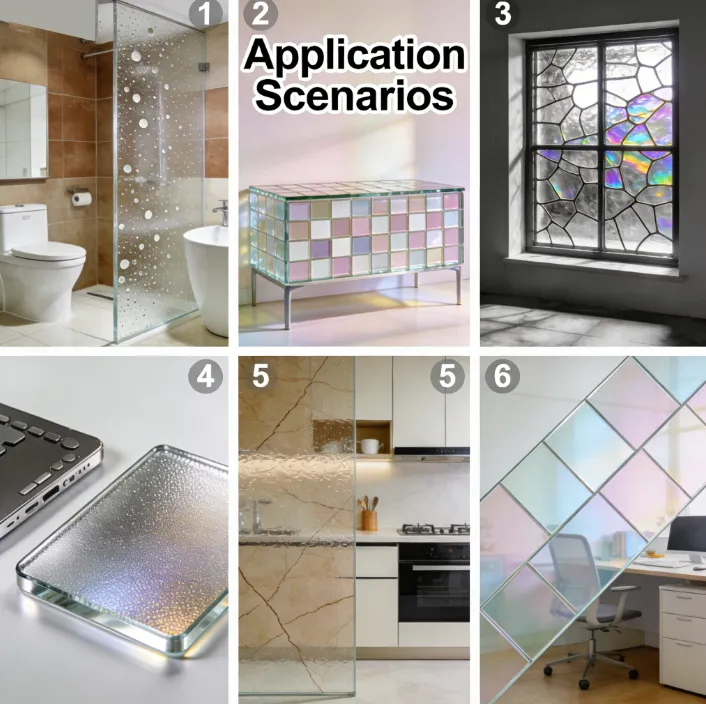

The scratch-resistant capabilities of modern Планшетные УФ-принтеры make them ideal for demanding architectural and commercial applications:

| Application Area | Glass Type | Durability Requirements | SENA Solution |

|---|---|---|---|

| Bathroom & Shower Doors | Tempered safety glass, clear & frosted | High scratch resistance, chemical resistance to cleaning agents | Multi-layer printing with protective topcoat |

| Commercial Windows | Insulated glass units, laminated glass | Weather resistance, UV stability, mechanical durability | Architectural-grade inks with enhanced cross-linking |

| Retail Partitions | Clear float glass, decorative patterns | Impact resistance, maintain appearance in high-traffic areas | Reinforced edge printing with extra protective layers |

| Restaurant & Kitchen Glass | Heat-resistant glass, easy-clean coatings | Resistance to abrasion, thermal cycling, chemical exposure | Specialized ink formulations for food service environments |

| Office Partitions | Acoustic glass, privacy glass | Long-term appearance maintenance, cleanability | Durable matte or glossy finishes as required |

| Hospital & Healthcare | Safety glass, antibacterial coatings | Chemical resistance to disinfectants, hygienic surfaces | Medical-grade compatible inks and coatings |

The scratch-resistant patterns produced by SENA УФ-струйные принтеры offer significant benefits across multiple industries:

Recognizing that different applications have unique durability requirements, SENA embraces a philosophy of complete customization: each size must meet the customer’s customized requirements.

Don’t miss this opportunity to benefit from our one-to-one customization service. Our engineering team works directly with clients to:

This collaborative approach ensures that every SENA UV flatbed printer is perfectly matched to its intended application, whether for boutique interior design projects or large-scale architectural glass production.

The newly launched SENA UV Printer series offers specialized solutions designed specifically for durable glass printing applications:

Область печати: 900×600mm

Best For: Medium-scale production, custom shower doors, retail partitions

Durability Features: 6 Ricoh printheads, enhanced curing system, optional protective coating module

View Technical Specifications →

Область печати: Custom configurations up to 2000×3000mm

Best For: Architectural glass manufacturers, large-format applications

Durability Features: 8 Ricoh printhead configuration, industrial curing, automated quality control

View Glass Printing Solutions →

Область печати: 2500×1300mm

Best For: Building facades, large office partitions, commercial windows

Durability Features: Heavy-duty construction, climate-controlled printing environment, multi-pass capability

View Architectural Solutions →

Область печати: Fully customizable

Best For: Specialized applications, unique size requirements, high-volume production

Durability Features: Complete customization, industry-specific optimizations, integrated automation

Request Custom Solution →

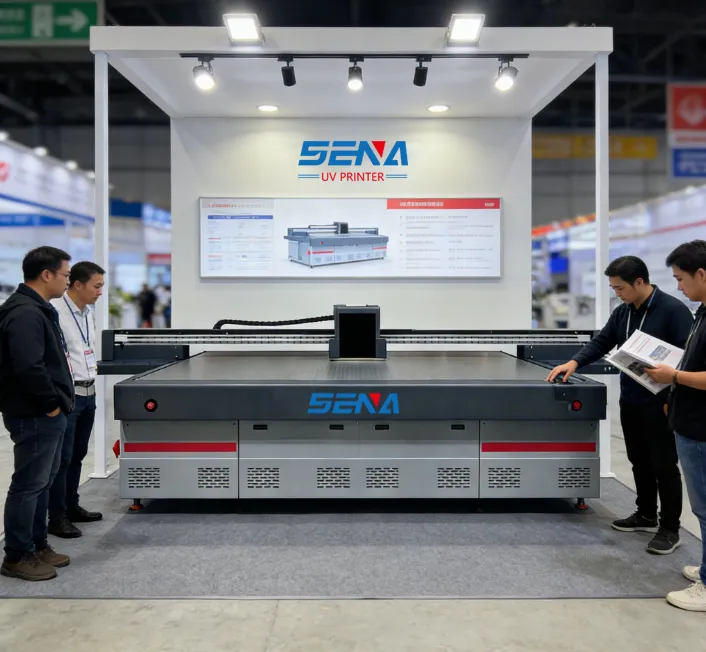

All SENA models feature factory-direct pricing, ensuring exceptional value without compromising quality. Each machine undergoes rigorous testing before shipment and includes comprehensive operator training focused on achieving maximum durability in finished products.

SENA’s commitment to producing scratch-resistant glass printing solutions is demonstrated through rigorous testing and comprehensive certification:

CE, UL, RoHS compliance for electrical safety and environmental standards

Independent laboratory test reports available for all durability claims

Compliance with architectural glass industry standards and specifications

ISO 9001:2015 certified manufacturing and quality control processes

These certifications and test results provide architects, specifiers, and manufacturers with confidence that patterns created with SENA Планшетные УФ-принтеры will maintain their appearance and functionality throughout their intended service life.

Investing in glass printing technology requires confidence in long-term support. SENA provides comprehensive global infrastructure to ensure ongoing success:

Beyond basic support, SENA offers specialized services for glass printing applications:

The advancement of УФ планшетный принтер technology has fundamentally changed the possibilities for durable glass decoration. With scratch-resistant patterns that withstand commercial and residential use, architects, designers, and manufacturers can now specify printed glass with confidence in its long-term performance.

SENA’s glass lithography machine series represents the cutting edge of this technology, combining precision engineering with proven durability. From bathroom doors and shower enclosures к commercial windows and architectural facades, these systems deliver both aesthetic excellence and practical durability.

Contact our glass printing specialists today for a personalized consultation. We’ll help you select the perfect УФ планшетный принтер configuration for your specific durability requirements and application needs.

Request Durability Consultation

Special Offer: Mention this article for a complimentary durability test on your glass samples.

Explore our specialized glass printing solutions →

Whether you’re producing architectural glass panels, commercial partitions, decorative elements, or specialty glass products, SENA’s multifunctional UV flatbed printers provide the technology, support, and proven durability needed for success in today’s demanding markets.