Evite que sua consulta atrase a resposta, insira seu WhatsApp/WeChat/Skype junto com a mensagem, para que possamos contatá-lo o mais rápido possível

Responderemos em até 24 horas. Se for um caso urgente, adicione WhatsApp: +86 17864107808, ou WeChat: +86 17864107808. Ou ligue +86 17864107808 diretamente.

*Respeitamos sua confidencialidade e todas as informações são protegidas. Usaremos suas informações somente para responder à sua consulta e nunca enviaremos e-mails ou mensagens promocionais não solicitados.

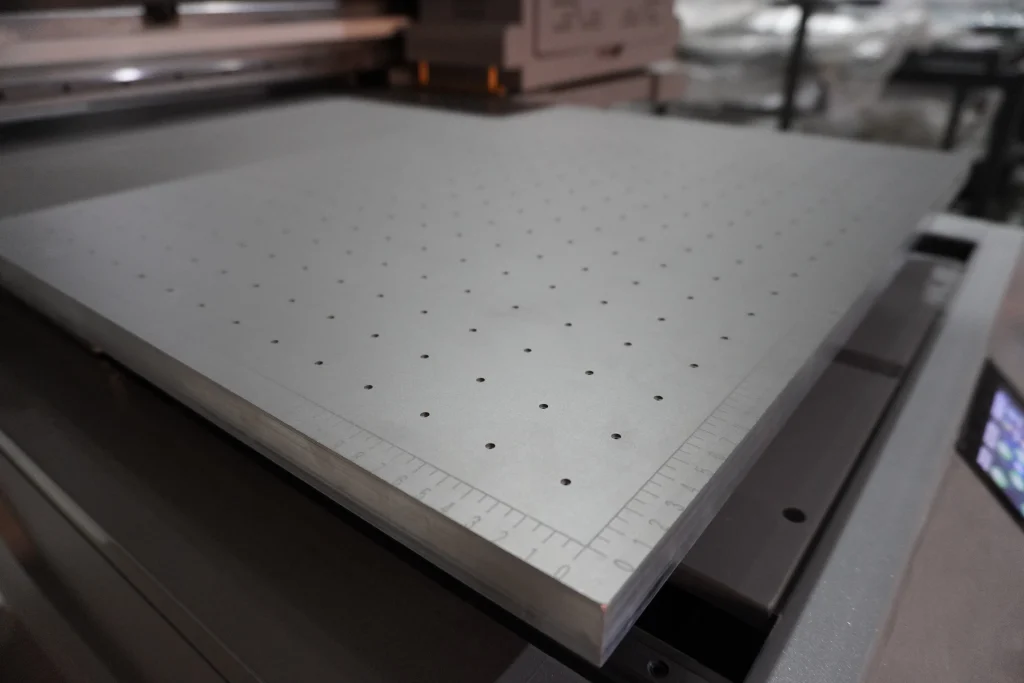

In the evolving world of digital printing, Impressoras planas UV stand out as a groundbreaking technology, offering precise, detailed printing on diverse materials. High precision UV flatbed printing machines are transforming industries, enabling users to print directly on substrates like acrílico, glass, metal, and even capas de telefone. This article delves into the intricacies of UV printing, its applications, and why it is essential for modern printing needs.

Impressoras planas UV are innovative máquinas de impressão that use luz ultravioleta para curar ou secar o Tinta UV as it is printed, allowing for stunning quality and durability on a variety of substrates.

These printers are ideal for industries requiring high-quality, durable prints that can withstand the test of time.

Impressoras UV use a unique process where the Tinta UV is printed directly onto the substrate and instantly cured with UV light.

This technology supports high resolution e high precision applications, making it invaluable in the print industry.

Tecnologia de impressão UV is used across various industries due to its flexibility and quality.

With its high precision, UV printing allows for creative, long-lasting solutions that cater to specific industry needs.

High precision UV printers provide unmatched detail and accuracy, crucial for fine art prints and technical applications.

These benefits are critical for businesses that prioritize detail and reliability in their printing projects.

Explore our range of Impressoras planas UV.

UV DTF (direto para filme) is a specialized UV printing process that involves printing on a film and then transferring the image to the intended material.

This method offers flexibility for complex designs and multi-layered prints across substrates.

UV inkjet printers offer significant advantages over traditional printing methods.

For high-quality, versatile printing options, UV inkjet remains the superior choice.

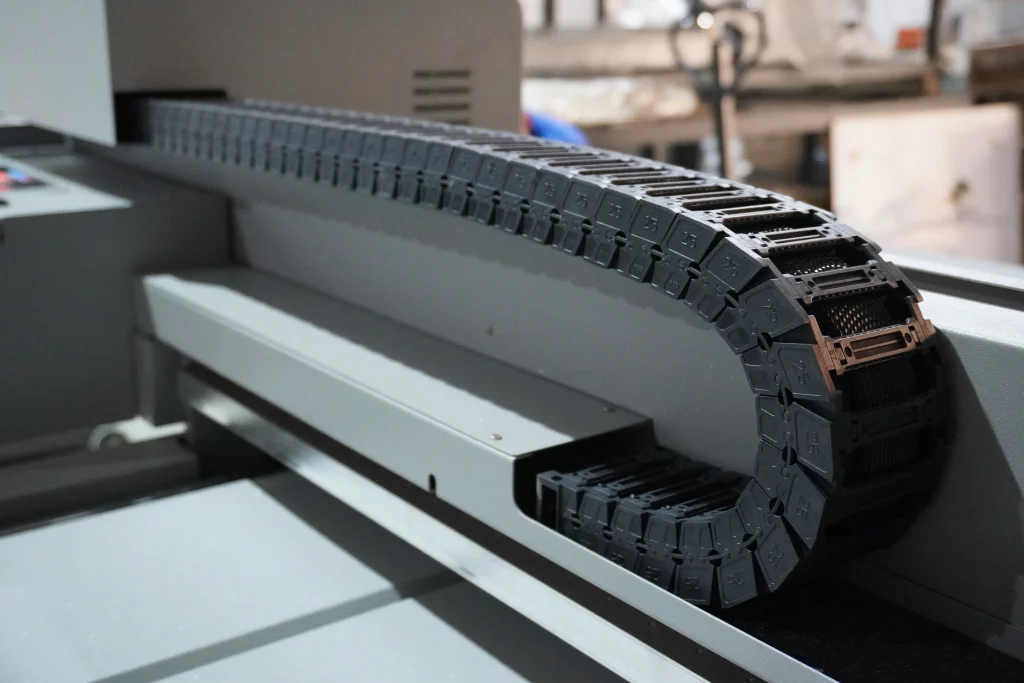

UM cabeça de impressão is a crucial component in UV printers, affecting speed, accuracy, and print quality.

Investing in high-quality print heads is essential for maintaining the reliability of a Impressora UV.

Selecting the ideal Impressora UV depends on your specific requirements and industry.

For comprehensive printing needs, Sublistar’s UV Flatbed Printer offers a versatile solution.

Tecnologia de impressão UV continues to advance, offering new opportunities and applications.

Staying ahead of these trends allows businesses to maintain a competitive edge and innovate continually.

Proper maintenance ensures that your Impressora UV continues to operate efficiently and produce high-quality outputs.

Consistent maintenance is crucial for preserving the printer’s lifespan and reliability.

Impressoras planas UV represent the pinnacle of high-precision and versatile printing technology. From intricate artworks to durable industrial components, their high performance meets diverse demands efficiently. By understanding the benefits, applications, and maintenance needs, businesses can harness these tools effectively, ensuring quality and innovation in their printing processes.

By investing in the right UV printing technology, you can achieve unparalleled results and meet the evolving demands of your industry.