Vermy jou navraag is vertragingsreaksie, voer asseblief jou WhatsApp/WeChat/Skype in saam met die boodskap, sodat ons jou die heel eerste keer kan kontak

Ons sal jou binne 24 uur antwoord. As vir 'n dringende saak, voeg asseblief WhatsApp by: +86 17864107808, of WeChat: +86 17864107808. Of bel +86 17864107808 direk.

*Ons respekteer jou vertroulikheid en alle inligting word beskerm. Ons sal slegs jou inligting gebruik om op jou navraag te reageer en sal nooit ongevraagde e-posse of promosieboodskappe stuur nie.

In the ever-evolving world of printing technology, UV flatbed UV LED printers are making a significant impact. This article delves into the intricacies of UV printing, exploring how these printers are revolutionizing the custom printing industry. Whether you’re a seasoned professional or new to the field, this comprehensive guide will provide valuable insights into why UV flatbed printers are worth your attention.

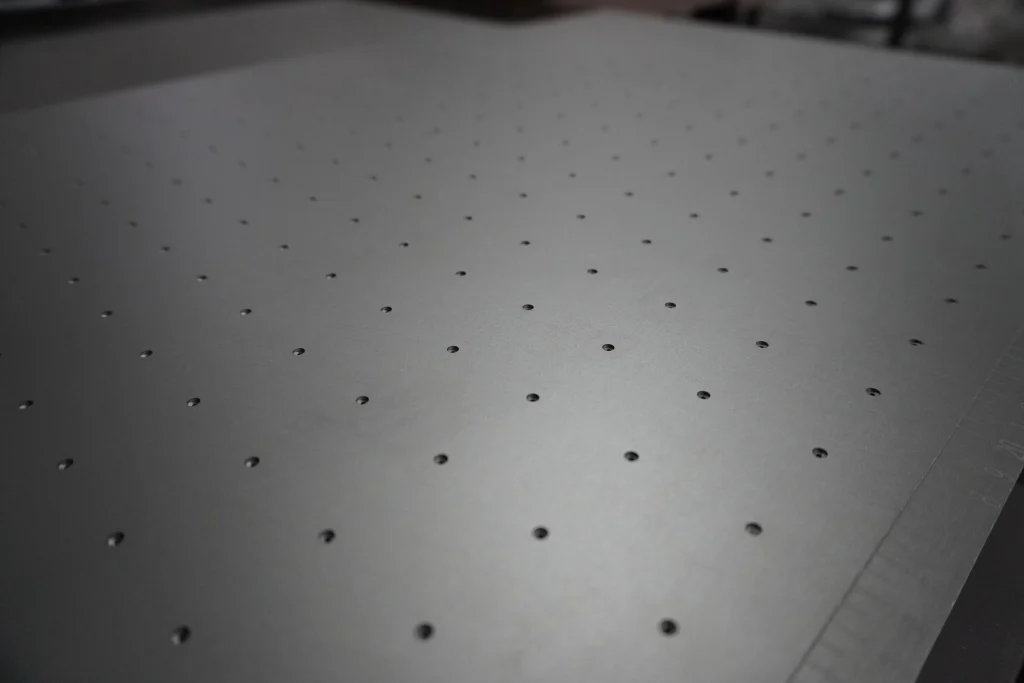

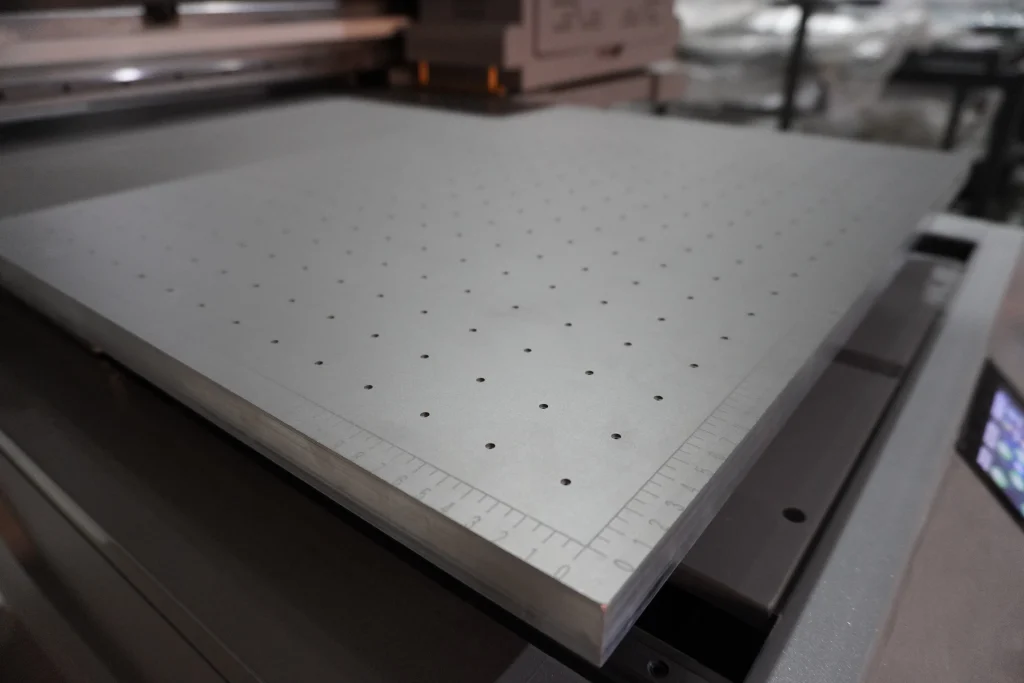

UV flatbed printing technology refers to a form of digital printing that uses ultraviolet (UV) light to dry or cure ink as it is printed. The drukker applies the UV ink directly onto the substrate, and UV light follows immediately to cure or dry the ink. This process allows for high-quality, durable prints on various materials.

UV-vlakbeddrukkers operate by moving the drukkop over a stationary substrate. The printer head deposits tiny droplets of UV ink onto the material, which are then immediately cured by UV light. This technology ensures precise printing with high resolution and excellent adhesion.

Belegging in 'n UV LED printer offers numerous benefits for businesses seeking to expand their product offerings and improve print quality.

Die drukkop is 'n kritieke komponent in UV-druktegnologie. It determines the print resolution, speed, and overall image quality.

UV ink are specially formulated to react to UV light, ensuring quick curing and durable prints.

High-droplet printing refers to the ability of a printer to deposit larger ink droplets, increasing print speed and efficiency.

Achieving the right balance between print speed en kwaliteit is essential.

Desktop UV flatbed printers are ideal for small to medium-sized businesses looking to offer custom printing services.

The customization capabilities of UV-drukwerk are vast, allowing businesses to cater to specific client needs.

A1: They can print on a variety of substrates including acrylic, PVC, ceramics, and more.

A2: UV-druk gebruik inks that are scratch-resistant and have excellent adhesion, resulting in durable prints.

A3: Yes, UV-LED curing is energy-efficient and emits less volatile organic compounds (VOCs).

Incorporating UV flatbed UV LED printers into your printing business can significantly enhance your product offerings and efficiency. With advancements in druk tegnologie, such as high droplet printing and instant UV curing, businesses can achieve hoë gehalte prints at high speeds.

For more information on UV printers, check out our High-Speed Fishing Rod Printer and explore how you can expand your business offerings.

Empower your printing capabilities with UV technology today!