Der neue UV-Flachbilddrucker durchbricht die Grenzen herkömmlicher Druckmaterialien

Katalog

Einführung: Einschränkungen der traditionellen Drucktechnologie

In der langen Geschichte der Entwicklung der Drucktechnologie erfüllen traditionelle Drucktechnologien wie Siebdruck, Tampondruck, Wassertransfer und Thermotransfer zwar bis zu einem gewissen Grad die Anforderungen des Marktes an die Musterwiedergabe, weisen jedoch viele Einschränkungen bei der Farbwiederherstellung, Materialanpassung und Druckeffizienz auf. Beispielsweise ist es mit der herkömmlichen Drucktechnologie schwierig, Vollfarbmuster auf allen Materialien zu reproduzieren, insbesondere auf nicht tintenabsorbierenden Materialien wie Möbeln, Fliesen und Glas. Diese technischen Mängel schränkten die Entwicklung der Druckindustrie ein, führten aber auch zur Entstehung neuer Drucktechnologien.

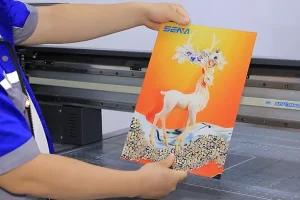

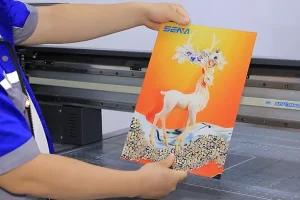

Wie zum Beispiel der UV-Flachbettdrucker SN-9060:

Der Aufstieg und die Vorteile von UV-Flachbettdruckern

In den letzten Jahren, mit der rasanten Entwicklung von Wissenschaft und Technologie, UV-Flachbettdrucker sind dank ihrer einzigartigen Vorteile und vielfältigen Anwendungsmöglichkeiten schnell zum neuen Liebling der Druckindustrie geworden. UV-Flachbettdrucker verwenden fortschrittliche piezoelektrische Tintenstrahldrucktechnologie und Ultravioletthärtungstechnologie, um effizienten Druck auf Knopfdruck und beim Trocknen zu erzielen und so die Materialbeschränkungen der herkömmlichen Drucktechnologie zu überwinden. Sie können in Vollfarbe auf Holz, Kunststoff, Metall, Glas, Keramik, Acryl und anderen Materialien drucken, mit leuchtenden Farben und klaren Schichten, und sie sind sehr langlebig und wasserdicht, ölbeständig, sonnenbeständig und bieten weitere Funktionen.

UV-Flachbettdrucker im Vergleich zum herkömmlichen Tintenstrahldrucker

Im Vergleich zu herkömmlichen Tintenstrahldruckern UV-Flachbettdrucker weisen in vielerlei Hinsicht klare Vorteile auf.

- Aushärtungsmethode: Die Tinte eines herkömmlichen Tintenstrahldruckers benötigt lange zum natürlichen Trocknen, während der UV-Flachbettdrucker die Tinte durch Ultraviolettbestrahlung sofort aushärtet, was die Druckeffizienz, insbesondere bei der Massenproduktion, erheblich verbessert.

- Materialanwendbarkeit: Tintenstrahldrucker unterliegen bestimmten Einschränkungen hinsichtlich der Druckmaterialien, häufig nur auf Papier und speziellen tintenabsorbierenden Materialien mit einer Dicke von weniger als 1 mm. Der UV-Flachbettdrucker kann auf fast jedem flachen Material drucken und hat einen breiteren Anwendungsbereich.

- Druckeffekt: Der UV-Flachbettdrucker kann mehr dreidimensionale und geprägte Muster drucken, da es in mehreren Schichten an derselben Stelle gestapelt werden kann. Der Druckeffekt von Tintenstrahldruckern ist relativ flach und die Farbleistung und der dreidimensionale Sinn sind schwach.

- Farbbeständigkeit: UV-Tinte ist witterungsbeständiger und verschleißfester, und das gedruckte Muster verblasst und nutzt sich nicht so leicht ab und bleibt lange Zeit hell und klar. Im Gegensatz dazu können mit Tintenstrahldruck gedruckte Muster bei direkter Sonneneinstrahlung und häufiger Reibung schneller verblassen und beschädigt werden.

Wie der UV-Drucker SN-6090:

Die breite Anwendung von UV-Flachbettdruckern

Aufgrund ihrer einzigartigen Vorteile werden UV-Flachbettdrucker in vielen Bereichen häufig eingesetzt.

- Werbefeld: einschließlich PVC-Karte, Plexiglas-Leuchtkasten, KT-Platte, PVC-Platte, Glas, Beschilderung, Gerätebedienfeld, Acryl, PP-Platte, PC-Platte usw.

- Verpackungsbereich: Weinverpackung, Papierverpackung, Holzverpackung, Metallverpackung, PVC-Verpackung, Lederverpackung, Plexiglasverpackung usw.

- Dekorationsbereich: Hintergrundwand (Hintergrundwand aus Keramikfliesen, Hintergrundwand aus Glas, Hintergrundwand aus PVC-Zwickel usw.), PVC-Zwickelplatte, PVC-Harzplatte usw.

- Digitale Elektronik: Handyhülle, Laptophülle, Hülle für mobile Stromversorgung, Festplattenhülle, Gehäuse für Stromzählerkästen, Gehäuse für Set-Top-Boxen usw.

- Bildprodukte und Kunsthandwerk: dekorative Ölgemälde, Lederprodukte, dekorative 3D-Gemälde, Bilderrahmen, Hochzeitsbilder usw.

Wie der UV-Flachbettdrucker SN-3045:

Technische Highlights der UV-Flachbettdrucker

Der Grund für die breite Einsatzmöglichkeit von UV-Flachbettdruckern in vielen Bereichen ist untrennbar mit ihren einzigartigen technischen Highlights verbunden.

- Fortschrittliche Farbmanagementtechnologie: wie etwa eine GCR-basierte Tintensparsteuerungstechnologie, eine hochpräzise Steuerungstechnologie zur Reduzierung von Sonderfarben und eine automatische Dreifarben-Graubalance-Steuerungstechnologie, damit die gedruckten Farben präziser und leuchtender sind.

- Effiziente Tintenzirkulationssysteme wie die interne Zirkulationstechnologie von RediJet verlängern die Arbeitszeit, reduzieren Ausfallzeiten und verbessern die Druckzuverlässigkeit durch kontinuierlichen Tintenzirkulationsfluss.

- Mithilfe flexibler Tröpfchensteuerungstechnologie, wie etwa der VersaDrop-Technologie mit variabler Tröpfchengröße, können Sie die Tröpfchengröße steuern und anwenden und so über den allgemeinen Graustufendruck hinaus die Feinheit und Schichtdicke des Drucks verbessern.

Zukunftsaussichten

Mit der zunehmenden Nachfrage nach Personalisierung, Umweltschutz, Effizienz und anderen Aspekten, die Marktaussichten von UV-Flachbettdrucker ist sehr breit. Insbesondere in den Bereichen Werbung, Dekoration, Verpackung usw. werden UV-Flachbettdrucker zu unverzichtbaren Produktionsgeräten. Gleichzeitig werden mit dem kontinuierlichen Fortschritt der Technologie und der schrittweisen Kostensenkung das Anwendungsfeld und der Marktanteil von UV-Flachbettdrucker wird weiter expandieren. Wir haben Grund zu der Annahme, dass der zukünftige UV-Flachbettdrucker seinen einzigartigen Charme und Wert in mehr Bereichen zeigen wird.

Häufig gestellte Fragen zu UV-Flachbettdruckern

- Kann UV-Flachbettdrucker zylindrische Gegenstände handhaben?

Obwohl sie in erster Linie für flache Substrate konzipiert sind, können einige UV-Flachbettdrucker mit Aufsätzen für den Druck auf zylindrischen Gegenständen wie Flaschen und Bechern ausgestattet werden.

- Welche Rolle spielt RIP-Software beim UV-Druck?

RIP-Software (Raster Image Processor) wie VersaWorks wandelt digitale Bilder in Anweisungen um, die der Drucker verstehen kann. Sie verwaltet Farbe, Layout und Druckqualität.

- Strahlen UV-Drucker schädliches UV-Licht aus?

UV-Drucker sind auf Sicherheit ausgelegt. Das UV-Licht ist umschlossen und nur auf die Tinte gerichtet, wodurch die Strahlenbelastung minimiert wird. Befolgen Sie immer die Sicherheitsrichtlinien des Herstellers.

- Wie schneidet der UV-Druck im Vergleich zu herkömmlichen Druckverfahren ab?

Der UV-Druck bietet im Vergleich zu herkömmlichen Druckverfahren schnellere Trocknungszeiten, eine größere Materialvielfalt und eine höhere Haltbarkeit.

- Ist für die Bedienung eines UV-Flachbettdruckers eine Schulung erforderlich?

Obwohl der Drucker benutzerfreundlich ist, empfiehlt sich eine gewisse Schulung, um die Funktionen des Druckers voll auszunutzen und eine gleichbleibende Druckqualität beizubehalten.

Die wichtigsten Erkenntnisse

- UV-Flachbettdrucker bieten Vielseitigkeit durch Direktdruck auf verschiedene Substrate.

- UV-Tinte sorgt für lebendige, haltbare Drucke, die sofort trocknen.

- Durch die Individualisierung werden die Geschäftsmöglichkeiten erweitert und die Kundennachfrage nach personalisierten Produkten erfüllt.

- Weiße Tinte verbessert Drucke auf dunklen oder transparenten Materialien.

- Desktop UV-Flachbettdrucker sind ideal für kleine Unternehmen.

- Der Einsatz fortschrittlicher Technologien wie der VersaOBJECT CO-Serie kann die Produktivität steigern.

- Die richtige Wartung und Optimierung sind für beeindruckende Drucke unerlässlich.