Évitez que votre demande ne soit retardée, veuillez saisir votre WhatsApp/WeChat/Skype avec le message, afin que nous puissions vous contacter dans les plus brefs délais.

Nous vous répondrons dans les 24 heures. En cas d'urgence, veuillez ajouter WhatsApp : +8617888313102, ou WeChat : +86 17864107808. Ou appelez +86 17864107808 directement.

*Nous respectons votre confidentialité et toutes les informations sont protégées. Nous n'utiliserons vos informations que pour répondre à votre demande et ne vous enverrons jamais de courriels ou de messages promotionnels non sollicités.

Struggling with slow print jobs, limited material options, or results that just don’t ‘wow’ your clients? These printing bottlenecks can stifle growth and impact your bottom line. It’s time to discover a solution that empowers your business with speed, versatility, and stunning quality, opening up new revenue streams.

A high-speed UV flatbed inkjet printer offers unparalleled versatility by printing directly onto a vast range of materials, from rigid boards to flexible films, using UV-curable inks. Its precision ensures vibrant, durable graphics with exceptional detail (high DPI). This makes it essential for businesses seeking top-tier print quality, rapid production for diverse applications, and expanded service offerings, ultimately boosting profitability by meeting varied customer demands efficiently.

As a leading UV Flatbed Printer Manufacturing plant, we’ve seen firsthand how this technology transforms businesses like yours. We’re here to share our expertise and guide you through the world of Impression UV.

You’ve likely heard the terms, but what exactly is a high-speed UV flatbed inkjet printer? At its core, this sophisticated machine à imprimer utilisations jet d'encre technology to propel tiny droplets of specially formulated Encre UV onto a stationary flat surface, known as the bed. The “flatbed” aspect means it can handle rigid and often thick materials, unlike roll-to-roll printers. The “UV” part refers to the curing process: powerful LED UV lamps accompany the têtes d'impression, emitting Lumière UV that instantly cures or hardens the encre as it’s deposited on the substrat. This instant curing is a game-changer.

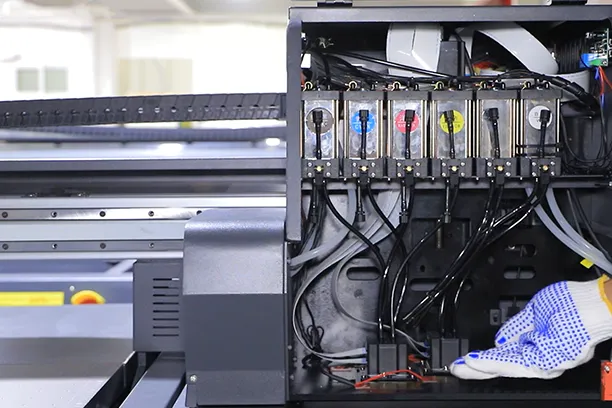

Ce Technologie UV offers several advantages. Because the encre cures immediately, there’s no smudging, and the printed items are ready for finishing or shipping right away. This dramatically speeds up the entire processus d'impression. Furthermore, LED UV curing is more energy-efficient and environmentally friendly than older mercury vapor lamp systems, producing less heat. This lower heat output also means a wider variété de matériaux, including heat-sensitive ones, can be printed on without warping or damage. We design our Imprimantes UV with advanced ink delivery system components for consistent results.

The precision of the imprimante à jet d'encre heads, combined with the rapid curing, allows for haute résolution graphics and crisp text. Whether you’re looking at a compact UV de bureau model for smaller items or a large-format industrial inkjet printer for extensive projects, the fundamental principle of precise dot placement and instant UV curing remains the same, delivering exceptional qualité d'impression. This type of imprimante is a significant step up from traditional méthodes d'impression.

For businesses in advertising, packaging, and industrial manufacturing, the final qualité d'impression is not just a feature; it’s a cornerstone of their brand and product appeal. When your Advertising & Logo Maker clients need vibrant, sharp logo reproduction, or a Packaging Printing Factory requires precise color matching for branding consistency, the capabilities of their Imprimante UV are paramount. The ability to achieve high DPI (dots per inch) translates directly into sharper images, smoother gradients, and more legible fine text. This accuracy ensures that the end graphique perfectly matches the digital design.

Consider the demands of articles promotionnels or detailed product labels. Imperfections, color shifts, or fuzzy details can undermine the perceived value of the product. A top-tier Imprimante UV ensures that every print is a faithful reproduction, maintaining brand integrity and customer satisfaction. As manufacturers, we focus heavily on the engineering of our imprimantes to guarantee this level of precision, from the stability of the flatbed to the accuracy of the têtes d'impression. This focus on results is why so many leading companies invest in advanced Impression UV solutions.

Furthermore, accuracy extends to color management. Professional Imprimantes UV often incorporate sophisticated RIP (Raster Image Processor) software and support for color profiles like CMJN with additional white and varnish options. This allows for consistent color output across different print runs and even different Imprimantes UV. For brands where color is a critical part of their identity, this reliability is non-negotiable. We understand these needs and build our Imprimantes à plat UV to deliver consistently superior printing results.

One of the most compelling advantages of a Imprimante à plat UV is its incredible versatilité when it comes to printing material types. Le direct-to-object printing capability, coupled with UV curing, means that the encre adheres exceptionally well to an astonishing gamme de matériaux. This opens up limitless possibilities for businesses looking to diversify their offerings. You’re no longer confined to paper or traditional sign media; you can print on a wide variety of materials.

Here’s a glimpse of what a UV flatbed printer can print sur:

This ability to print on nearly any substrate is revolutionary. Imagine offering custom Impression de coque de téléphone, personalized wooden boxes for a Gift Customization Company, or durable, branded components for Industrial Manufacturing Companies. The adhérence de l'encre provided by Encre UV technology is robust, ensuring longevity even on non-porous surfaces. As a UV Flatbed Printer Manufacturing plant, we rigorously test our machines with a variété de substrats to ensure optimal performance and adhérence de l'encre for our clients, including those looking for specific directement sur le substrat solutions.

A common question we hear is whether you have to sacrifice quality for speed, or vice-versa, with Impression UV. The good news is that modern high-speed UV flatbed printers are engineered to deliver both. Advances in têtes d'impression technology, sophisticated motion systems, and highly efficient LED UV curing systems mean that you can achieve rapid production without compromising on the fine details or color vibrancy that define de haute qualité output. This is particularly crucial for businesses with high-volume demands or tight deadlines, such as Printing Service Providers or UV Printing OEM Factories.

The key lies in the synergy of components. uv inkjet printer printheads, for example, can lay down encre at incredible speeds, while the immediate UV curing locks the droplets in place before they can spread or bleed, preserving sharpness. Features like bi-directional printing and optimized print path algorithms further enhance throughput. For operations requiring continuous printing, the robust build of an impression industrielle grade Imprimante UV ensures reliability shift after shift. This allows for impressive turnaround times, a critical factor for staying competitive.

Of course, there’s always a spectrum. Printing at the absolute highest DPI might take slightly longer than a draft mode, but even at their top production speeds, the quality from a professional Imprimante à plat UV remains exceptionally high. We design our imprimantes with various print modes, allowing you, the user, to balance speed and quality based on the specific job requirements. This flexibility ensures you can meet diverse client needs, from rapid prototyping to producing couleur exhibition graphics where every detail matters. The development of such printers,

The thought of integrating a sophisticated piece of equipment like a Imprimante à plat UV can sometimes seem daunting, especially concerning the operating difficulty. However, as manufacturers, we’ve invested heavily in making our imprimantes as user-friendly as possible. Modern Imprimantes UV come with intuitive touchscreen interfaces, streamlined workflow software, and automated maintenance routines. This significantly reduces the learning curve for your team.

Most high-quality flatbed inkjet printers are bundled with powerful RIP software that simplifies job setup, color management, and print queue organization. These software suites often include features like automatic nesting of jobs to maximize material usage and minimize waste. Furthermore, many routine tasks, such as nozzle checks and head cleanings, can be automated or semi-automated, ensuring your imprimante stays in peak condition with minimal manual intervention. We also provide comprehensive training when you invest in one of our machines, ensuring your operators are confident and competent.

While the underlying Technologie UV is complex, operating the imprimante itself is designed to be straightforward. Think of it like any other advanced digital tool in your production environment. With proper training, which we proudly offer, your existing staff can quickly become proficient in managing print jobs, performing basic maintenance, and unlocking the full potential of your Imprimante à plat UV. This ease of use is a key consideration for businesses like Home Decoration Companies or Gift Customization Companies that may not have dedicated, highly technical print operators.

Investir dans un Imprimante à plat UV is a significant decision for any business. It’s not just about the initial purchase; it’s about the long-term performance, reliability, and support you receive. This is where after-sales service and a comprehensive warranty become absolutely critical. As a UV Flatbed Printer Manufacturing plant, we firmly believe that our relationship with you extends far beyond the point of sale. We understand that downtime can be costly, and quick, effective support is essential to keep your operations running smoothly.

A robust warranty provides peace of mind, covering potential manufacturing defects and ensuring that key components of your imprimante are protected. But equally important is the after-sales service. This includes access to skilled technicians for troubleshooting and repairs, readily available spare parts, and ongoing software updates. When you partner with us, you gain access to a dedicated support team that understands your Imprimante UV inside and out. Explore our comprehensive after-sales service and warranty packages to see how we protect your investment.

Think about it: whether you’re an Advertising & Logo Maker needing urgent support before a big client presentation or an Industrial Manufacturing Company relying on continuous printing for your production line, responsive service is invaluable. We offer various levels of support, from phone and online assistance to on-site technician visits. This commitment to service is what differentiates a reliable uv inkjet printer partner from just a supplier. It’s a cornerstone of our promise to you.

The true power of a Imprimante à plat UV is best seen in its diverse applications across various industries. Its ability to perform impression directe onto a multitude of substrates unlocks new creative and commercial opportunities. For instance, Home Decoration Companies can use Imprimantes UV to create custom wallpaper, print directly onto wooden panels for unique wall art, or even personalize ceramic tiles for kitchens and bathrooms. The possibilities for Personnalisation are virtually endless.

Gift customization companies thrive on uniqueness. A Imprimante à plat UV allows them to offer personalized phone cases (Impression de coque de téléphone), custom awards, engraved-look items on acrylique, and much more. Brands can leverage this technology for short-run, high-impact articles promotionnels and point-of-sale displays that truly stand out. We’ve seen clients achieve remarkable success by integrating Impression UV into their workflows. For example, some are now offering Impression UV DTF (Direct-to-Film) for apparel and irregular surfaces, or intricate sticker printing with textured effects.

Furthermore, consider the impact on industrial applications. Manufacturers can use uv machine for durable part marking, creating custom control panels, or printing directly onto enclosures. The adhérence de l'encre and resistance to abrasion and chemicals make Encre UV ideal for such demanding environments. Printing service providers can expand their offerings significantly, catering to a broader client base with unique products that traditional méthodes d'impression simply can’t produce. The versatilité means one machine à imprimer can serve many different markets and needs, from simple signage to complex, multi-layered graphics.

Beyond standard flat-surface printing, many modern Imprimantes UV offer advanced capabilities that can further expand your creative and production horizons. One such exciting feature is cylindrical UV printing. Specialized jigs or integrated rotary attachments allow the imprimante to print directly onto cylindrical or tapered objects like bottles, tumblers, candles, and industrial pipes. This opens up entirely new markets for personalization and branding, a capability highly sought after by gift companies and brands wanting unique packaging. Our range includes printers with optional cylindrique attachments.

Another indispensable feature for professional Impression UV est white ink circulation. White Encre UV is crucial for printing on dark or transparent substrates, as it provides an opaque base layer for the CMJN colors to pop. However, white encre pigments are heavier and can settle, leading to nozzle clogs. A white ink circulation system continuously agitates the encre, ensuring it remains properly mixed and ready to print, minimizing maintenance and ensuring consistent opacity. This feature, coupled with the ability to print clear varnish for spot gloss or textured effects, adds significant value and allows for premium finishes.

These advanced features, including sophisticated ink delivery systems et précis têtes d'impression, are what set high-end Imprimantes UV apart. The ability to perform directement sur le substrat printing with such finesse and added effects like embossing or Braille elevates the types of products you can offer. While some might consider a desktop UV printer for smaller tasks, businesses looking for maximum versatility and impact should explore machines equipped for these specialized UV printer uses, including options for bulk ink systems to reduce running costs on high-volume jobs.

Sélection du l'imprimante est la meilleure suited for your specific requirements involves careful consideration of several factors. There’s no one-size-fits-all answer, as the ideal machine d'impression uv for an Advertising & Logo Maker might differ from that of an Industrial Manufacturing Company. Start by evaluating your primary printer uses: What types of products will you be printing most often? What is the maximum size and thickness of the substrat you need to accommodate? This will help determine the necessary bed size and Z-axis clearance of the imprimante à plat.

Next, consider your production volume and speed requirements. If you need grande vitesse output for large runs, an industrial inkjet printer with features like continuous printing capabilities would be more appropriate than a smaller, entry-level UV de bureau model. Conversely, if your focus is on short-run Personnalisation and intricate detail, a imprimante with ultra-high DPI capabilities might be prioritized. Don’t forget to factor in your workspace; ensure you have adequate room for the imprimante and any associated finishing equipment. Our experts can help you assess your needs and request a personalized consultation with our UV printing experts.

Finally, evaluate the total cost of ownership, not just the initial purchase price. This includes the cost of Encre UV (consider bulk ink systems vs. ink cartridge options), consumables, maintenance, and the value of the after-sales service and warranty provided by the UV Flatbed Printer Manufacturing plant. Investing in a reliable imprimante à plat from a reputable manufacturer with strong support can save you significant money and headaches in the long run. We encourage you to discuss your needs with us; we can guide you to the Imprimante à plat UV that will be a true asset to your business.

What is the typical lifespan of a UV flatbed printer?

The lifespan of a Imprimante à plat UV can vary depending on the build quality, usage intensity, and maintenance. A well-maintained industrial printing machine from a reputable manufacturer like us can last for many years, often 7-10 years or even longer, though key components like têtes d'impression will require replacement periodically as part of regular maintenance. Consistent upkeep is key to maximizing its operational life.

Can UV printers print on dark or transparent materials effectively?

Yes, absolutely! Modern Imprimantes UV are equipped with white Encre UV, which is essential for printing on dark or transparent substrates. The white encre is laid down as an opaque base layer, allowing the subsequent CMJN colors to appear vibrant and true, rather than being lost or dulled by the material’s color. Effective white ink circulation systems in quality Imprimantes UV ensure this capability is always reliable.

How does UV printing compare to other printing methods like screen printing or solvent printing?

Impression UV offers several advantages over traditional methods. Compared to screen printing, digital UV printing is much faster for short to medium runs, requires no screen setup, and allows for easy Personnalisation and variable data printing. Unlike solvent printing, Encre UV cures instantly with Lumière UV, producing no VOCs (Volatile Organic Compounds), resulting in a more environmentally friendly processus d'impression and immediately usable prints. It also offers superior adhérence de l'encre on a wider variété de matériaux.

What kind of maintenance does a UV flatbed printer require?

Regular maintenance is crucial for optimal performance and longevity of any Imprimante UV. Typical tasks include daily and weekly cleaning of têtes d'impression and capping stations, checking encre levels (whether from an ink cartridge ou bulk ink system), and ensuring the LED UV lamps are clean. Most modern Imprimantes UV have automated or semi-automated cleaning cycles. As manufacturers, we provide detailed maintenance schedules and training.

Are the inks used in UV printers safe and environmentally friendly?

Encres UV are generally considered more environmentally friendly than solvent-based inks because they are VOC-free and the LED UV curing process is energy-efficient. Many Encre UV formulations are also designed for safety, and some, like those we offer, can achieve certifications such as GREENGUARD GOLD certified, making them suitable for indoor applications, including schools and healthcare facilities.

How can a UV printer help my specific business, for example, if I’m a Home Decoration Company?

If you’re a Home Decoration Company, a Imprimante UV opens up a world of Personnalisation. You can print directly onto wood for custom wall art, create bespoke ceramic tiles, produce personalized canvas prints, or even print on glass for unique partitions or tabletops. The ability to offer unique, high-quality, and durable decorative items can significantly differentiate your business and attract more customers looking for personalized home décor solutions. The versatilité de direct-to-object printing is a major asset.

Ready to revolutionize your printing capabilities and unlock new market opportunities? As experienced UV Flatbed Printer Manufacturing plants for products, we are here to help you choose the perfect Imprimante UV solution tailored to your unique business needs.

Contact us today for a personalized consultation or a live demonstration, and let’s explore how our advanced UV flatbed inkjet printers can elevate your business!