Izbjegnite da vaš upit kasni s odgovorom, unesite svoj WhatsApp/WeChat/Skype zajedno s porukom kako bismo vas mogli kontaktirati prvi put

Odgovorit ćemo vam u roku od 24 sata. Ako je hitan slučaj, dodajte WhatsApp: +86 17864107808, ili WeChat: +86 17864107808. Ili nazovite +86 17864107808 direktno.

*Poštujemo vašu povjerljivost i svi podaci su zaštićeni. Koristit ćemo vaše podatke samo kako bismo odgovorili na vaš upit i nikada nećemo slati neželjenu e-poštu ili promotivne poruke.

Zamislite da možete ispisivati živopisne, detaljne slike izravno na kožne proizvode s lakoćom i preciznošću. Zahvaljujući UV ravnim pisačima, ovo je sada stvarnost. U ovom ćemo članku istražiti kako UV tisak na koži transformira industriju, omogućujući izradu prilagođenih kožnih predmeta kao nikada prije. Otkrijte zašto je ova vrhunska tehnologija vrijedna vaše pažnje i kako može koristiti vašem poslovanju ili kreativnim projektima.

UV tisak na koži moderan je proces digitalnog ispisa koji koristi ultraljubičasto (UV) svjetlo za stvrdnjavanje ili sušenje tinte dok se ispisuje na kožne površine. Ova metoda omogućuje visokokvalitetne, izdržljive ispise na različitim vrstama kožnih materijala, uključujući pravu kožu, umjetnu kožu i PU kožu. UV printer primjenjuje se UV tinta na koži, tinta se odmah stvrdnjava UV svjetlom, što rezultira brzim i učinkovitim procesom ispisa. Ova vam tehnologija omogućuje ispisati izravno na kožu, stvarajući zapanjujuće proizvodi od kože zamršenog dizajna i živih boja.

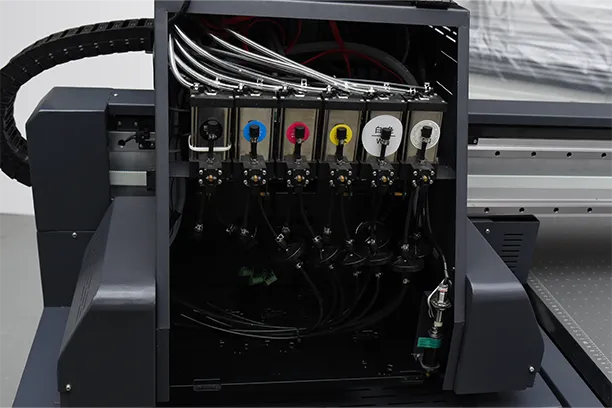

UV plošni pisači su specijalizirani tiskarski strojevi dizajniran za rukovanje različitim materijalima, uključujući kožu. "Flatbed" se odnosi na ravnu površinu na koju se postavlja materijal tijekom ispisa. Evo jednostavnog pregleda rada ovih pisača:

Ovaj postupak rezultira oštrim, živopisnim slikama koje su izdržljive i otporne na blijeđenje.

Nekoliko je prednosti korištenja UV tisak na koži:

Ove prednosti čine UV tisak odličnim izborom za tvrtke koje žele unaprijediti svoje kožne proizvode.

UV plošni pisači sposobni su za ispis na širokom rasponu vrsta kože, uključujući:

Bilo da radite sa prava koža ili materijali od umjetne kože poput PU kože, UV pisači mogu učinkovito obaviti posao.

Odabir odgovarajućeg stroj za tiskanje kože ključna je za postizanje najboljih rezultata. Razmotrite sljedeće čimbenike:

Jedan primjer pouzdanog pisača je SN-2513G veliki UV plošni pisač, poznat po velikim visinama ispisa i vrlo preciznim ispisima.

UV tinta posebno je formuliran za rad sa sustavima UV sušenja u pisačima. Njegove ključne karakteristike uključuju:

Koristeći pravo tinta neophodna je za visoku kvalitetu digitalni tisak na koži.

S UV tehnologijom tiska, stvarajući prilagođena koža proizvoda nikada nije bilo lakše. Tvrtke i pojedinci mogu personalizirati stavke kao što su:

Personalizirani UV ispis omogućuje jedinstvene dizajne, monograme ili brendiranje izravno na kožni predmeti, dodajući vrijednost i privlačnost.

Ispis izravno na kožu uključuje nekoliko koraka:

Ovaj proces tiskanja je jednostavan i omogućuje visoku prilagodbu i učinkovitost.

Kako biste osigurali optimalne rezultate ispisa na koži, imajte na umu ove savjete:

Slijeđenje ovih smjernica pomoći će vam da maksimalno povećate mogućnosti svog UV pisač za kožu.

UV plošni pisači otvorili su nove horizonte u svijetu tiska na koži. Od modnih dodataka do personaliziranih darova, mogućnost da ispisati izravno na kožu nudi beskrajne mogućnosti. Razumijevanjem tehnologije i odabirom prave opreme, svoje kožne proizvode možete podići na nove visine.Ključni zaključci:

Jeste li spremni transformirati svoje kožne proizvode tehnologijom UV tiska? Istražite našu ponudu UV plošni pisači i pronaći savršeno rješenje za ispis za svoje potrebe.