Vermy jou navraag is vertragingsreaksie, voer asseblief jou WhatsApp/WeChat/Skype in saam met die boodskap, sodat ons jou die heel eerste keer kan kontak

Ons sal jou binne 24 uur antwoord. As vir 'n dringende saak, voeg asseblief WhatsApp by: +8617888313102, of WeChat: +86 17864107808. Of bel +86 17864107808 direk.

*Ons respekteer jou vertroulikheid en alle inligting word beskerm. Ons sal slegs jou inligting gebruik om op jou navraag te reageer en sal nooit ongevraagde e-posse of promosieboodskappe stuur nie.

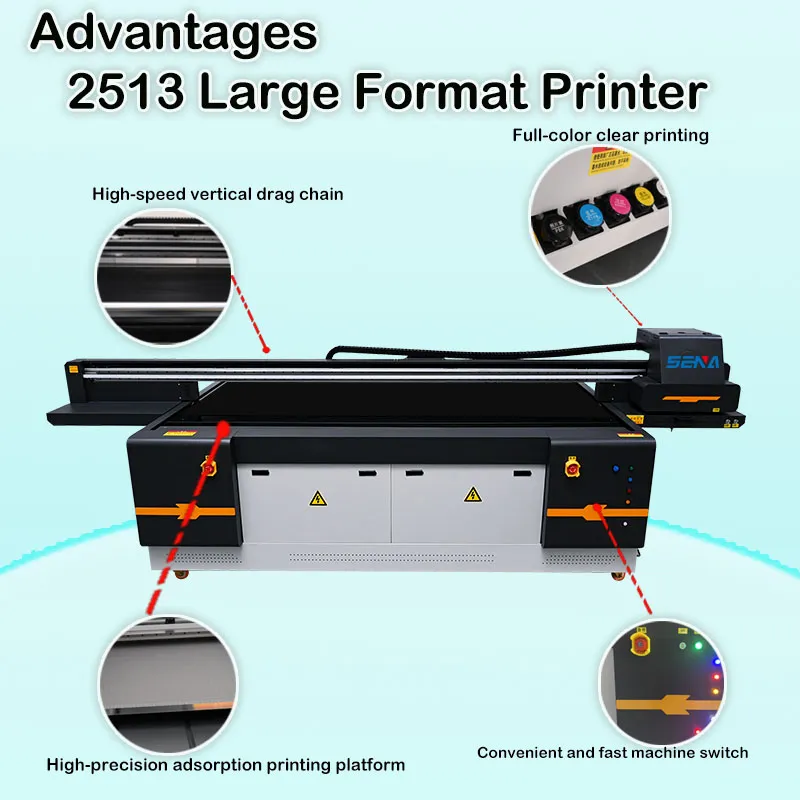

The automotive advertising industry is undergoing a transformation with SENA’s latest UV platbed drukker technology, achieving threefold printing speed for vehicle wraps. This breakthrough combines advanced inkjet technology with intelligent automation systems, offering unprecedented efficiency while maintaining hoë kwaliteit drukwerk across diverse materials.

SENA’s new generation UV inkjet drukker integrates Ricoh G6 industrial print heads that deliver 2400dpi resolution at twice the speed of conventional models. The optimized inkjet technology reduces material transfer time by 40% through:

Compared to traditional screen printing, this UV drukker achieves full-color vehicle wraps in 1/3 the time while eliminating plate-making costs. (SN-2513E Groot UV-platbeddrukker)

Die multifunction UV flatbed printer handles over 20 substrates including:

For automotive applications, the system excels in telefoonkas druk on ABS plastic and metallic finishes on alloy wheels. The piezoelectric nozzles automatically adjust ink formulations for each material type. (SN-1610 Medium UV-platbeddrukker)

Key innovations driving productivity include:

The integrated workflow reduces manual intervention by 75%, making it ideal for high-volume buitelugtekens production. (SN-9060 Medium UV-platbeddrukker)

Case Study 1: Fleet Graphics Production

A national logistics company reduced vehicle wrapping time from 8 hours to 2.5 hours per truck using SENA’s UV flatbed solution. The system printed directly on 3M cast vinyl with metallic ink, achieving 5-year outdoor durability.

Case Study 2: Custom Car Wraps

An auto customization shop increased daily capacity from 3 to 12 vehicles using the klein UV-vlakbeddrukker for prototype development. The 300×450mm format proved ideal for hood and door panel designs.

Case Study 3: Ceramic Tile Printing

An architectural firm adopted the system for vehicle-themed mural production on ceramic tiles, achieving 98% Pantone color matching with UV varnish printing capability.

| Model | Druk Area | Max Media Thickness | Ideal Applications |

|---|---|---|---|

| SN-3045 | 300×450mm | 240mm | Prototypes, small parts |

| SN-9060 | 900×600mm | 500mm | Door panels, hoods |

| SN-1610 | 1600×1000mm | 120mm | Full vehicle sides |

| SN-2513E | 2500×1300mm | 50mm | Bus wraps, trailers |

SENA’s UV printing technology redefines automotive advertising through:

Vir besighede wat soek flatbed printer for sale, SENA offers tailored financing packages and operator training programs. The system’s ROI becomes apparent after processing just 150 vehicle wraps, with annual maintenance costs below 8% of equipment value.

Contact SENA Printing Group at +86 17888313102 or visit www.uvflatbedprinters.com to schedule a free sample printing demonstration.