Vermy jou navraag is vertragingsreaksie, voer asseblief jou WhatsApp/WeChat/Skype in saam met die boodskap, sodat ons jou die heel eerste keer kan kontak

Ons sal jou binne 24 uur antwoord. As vir 'n dringende saak, voeg asseblief WhatsApp by: +8617888313102, of WeChat: +86 17864107808. Of bel +86 17864107808 direk.

*Ons respekteer jou vertroulikheid en alle inligting word beskerm. Ons sal slegs jou inligting gebruik om op jou navraag te reageer en sal nooit ongevraagde e-posse of promosieboodskappe stuur nie.

Having issues with subpar or unaesthetic prints on differing materials? Missing out on potential profits due to outdated printing technology? Advanced Mechanical offers custom grade printing solutions to meet the goals of any business as a UV Flatbed Printer Manufacturing plant.

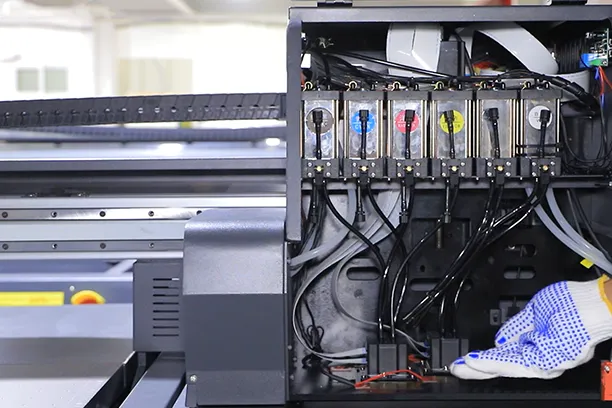

Our experienced engineers specialize in designing, constructing and upholding superb UV flatbed and hybrid roll to roll printers. Our proprietary robust printers use specialized UV ink that is instantly cured by UV LED lights. That said, choosing the right supplier from countless competing manufacturers is essential to unlocking unparalleled technology alongside expert-level support tailored to custom industrial grade on-demand printing and laser engraving systems.

Let’s touch base on the essentials. UV printing is a type of digital printing that uses ultra violet (UV) light to cure or dry put ink on a surface almost immediately. In comparison to traditional printing methods, UV printing does not require time for the ink to dry, or if it does, it uses heat instead. After the UV light is applied to the surface, the ink transforms into a strong layer.

Hierdie druk tegnologie behels inkjet print heads precisely jetting tiny droplets of liquid UV ink onto a substrate – which could be anything from rigid boards to flexible films. Immediately following the ink deposition, high-intensity UV LED lamps pass over the printed area, initiating a photochemical reaction that solidifies the ink. This means prints are dry and ready for finishing or shipping right off the drukker.

As 'n UV Flatbed Printer Manufacturing plant, we engineer our machines to optimize this process. We focus on the precision of the inkjet system, the efficiency and longevity of the UV LED curing units, and the overall mechanical accuracy of the platbed drukkers to ensure consistent, high-resolution output every single time. This technology opens doors for verskeie drukwerk applications previously difficult or impossible to achieve efficiently.

Hierdie druk tegnologie behels inkjet print heads precisely jetting tiny droplets of liquid UV ink onto a substrate – which could be anything from rigid boards to flexible films. Immediately following the ink deposition, high-intensity UV LED lamps pass over the printed area, initiating a photochemical reaction that solidifies the ink. This means prints are dry and ready for finishing or shipping right off the drukker.

As 'n UV Flatbed Printer Manufacturing plant, we engineer our machines to optimize this process. We focus on the precision of the inkjet system, the efficiency and longevity of the UV LED curing units, and the overall mechanical accuracy of the platbed drukkers to ensure consistent, high-resolution output every single time. This technology opens doors for verskeie drukwerk applications previously difficult or impossible to achieve efficiently.

What are the reasons to select a UV flatbed printer over other printer technologies?

Other forms of printing technology might not compete well with the convenience offered by a UV flatbed printer for businesses that need its versatility. A UV flatbed printer has immense advantages because of the direct printing onto thick rigid substrates like wood, acrylic, glass, metal, and ceramics. Unlike traditional printers that use inkjet technology and have inflexible substrate material, inkjet uv printer use a stationary material so that the printer head assembly can move along the substrate.

What are the reasons to select a uv druk masjien over other printer technologies?

Other forms of printing technology might not compete well with the convenience offered by a uv printer machine for businesses that need its versatility. A UV flatbed printer has immense advantages because of the direct printing onto thick rigid substrates like wood, acrylic, glass, metal, and ceramics. Unlike traditional printers that use inkjet technology and have inflexible substrate material, UV flatbed printers use a stationary material so that the printer head assembly can move along the substrate.

This ability serves a transformational role across various business sectors. Custom sign makers will be able to make amazing outdoor advertising signs with non-traditional materials. Custom corrugated board or box printing for packaging factories is also facilitated because they can print directly onto these packaging materials. Wood, glass, and even wallpaper can be printed by home decoration firms. Almost any object can be personalized, which is an advantage gift customization companies can offer. Many different industries can benefit from the use of a UV Flatbed printer because the ink is applied directly to the surface without needing to have special coatings beforehand.

When evaluating a UV platbed drukker, several features stand out, directly impacting performance and usability. These are facets we carefully technology at our factory:

We design our UV-vlakbeddrukmasjiene with these critical components integrated seamlessly, focusing on durability, ease of maintenance, and delivering the drukkwaliteit and accuracy our clients demand. Understanding these features helps you compare different types of uv printers effectively.

This is where UV drukkers, particularly UV-vlakbeddrukkers, truly excel. Their ability to print on an incredibly diverse range of materials is a primary reason for their adoption across so many industries. The UV ink curing process allows adhesion to surfaces where traditional inks would fail.

Here’s a glimpse of the material compatibility:

This versatility means one UV-drukmasjien can serve multiple purposes. An advertising agency can print banners, rigid signs, and promosie produkte. A packaging company can prototype boxes and print directly onto finished containers. Industrial manufacturers can add durable labels or markings directly onto parts. As a manufacturer of uv printers, we ensure our machines, like the popular A3 uv flatbed printer for smaller items or the grootformaat drukker for bigger jobs, have adjustable print head heights and robust vacuum systems precisely to accommodate this wide material range. Our printer can print on substrates up to several inches thick.

The perennial question in any printing operation! UV drukkers offer a spectrum of print modes that allow users to prioritize either speed or quality, or find a suitable balance between the two. Understanding customer needs and managing client schedules on a case by case basis requires this level of flexibility.

High-Quality/Fine Art Modes: Employ the maximum number of passes, smaller droplets, and slower print head speeds. In intricate graphics, photographic reproductions, and other work involving significant detail and thorough scrutiny, this guarantees the utmost possible resolution, the smoothest gradients, and the most refined details.

Factors influencing this balance include the print head technology, the RIP software’s capabilities, and the UV uitharding system’s efficiency. As manufactures, we enable advanced operators to generate custom profiles, but we do offer set print modes that can be applied with little to no operator experience. Our grootformaat UV-drukkers are often equipped with multiple rows of print heads specifically to achieve higher speeds without compromising quality significantly. It’s about providing the tools for jou print business to choose the optimal setting for each specific job, whether it’s rapid production of promosie produkte or meticulous varnish printing effects on luxury packaging.

Die veelsydigheid van UV-drukwerk, especially UV-vlakbeddruk, makes it a valuable asset across numerous sectors. We see tremendous success among our clients in these areas:

Essentially, any business needing high-quality, durable digitale drukwerk on a variety of materials, especially rigid or unconventional ones, can benefit significantly from investing in a UV drukker. Die machine can be used for an incredibly broad range of profitable applications.

Selecting a UV drukker is a significant investment. Partnering with the right UV drukker vervaardiger is just as crucial as choosing the machine itself. Your target audience focuses on multiple factors at once, and here is how a reputable manufacturer solves

them:

Beyond these core points, consider the manufacturer’s experience, industry reputation, innovation (e.g., advancements in UV LED technology or ink formulations), and willingness to understand your specific drukbehoeftes. Building a relationship with your UV drukker vervaardiger ensures ongoing success.

Die UV printer price can vary significantly based on several factors: size (A3 UV drukker vs. groot formaat UV platbed), speed (number/type of print heads), features (white ink, varnish, roll-to-roll capability), brand reputation, and included support/warranty. A small uv printing machine of lessenaar UV model might start in the low tens of thousands of dollars, while high-production large format uv printers can cost hundreds of thousands.

It’s crucial to look beyond the initial purchase price and consider the Total Cost of Ownership (TCO) and Return on Investment (ROI). TCO includes the drukker cost, ink consumption, energy usage, maintenance, consumables (like UV LED lamps eventually needing replacement), and labor. ROI is calculated by considering the revenue generated through new applications, increased efficiency, reduced outsourcing costs, and higher-value products enabled by the UV drukker.

For example, a packaging company investing in a platbed UV drukker might see ROI by:

Similarly, a home decor company using a UV drukker vir hout of doek drukwerk can create unique, high-margin products. We, as the drukker vervaardiger, can help you analyze potential ROI based on your specific business model and the capabilities of our drukmasjiene, like the versatile UV6090 Flatbed UV Printer. Understanding the types of uv printers and their costs relative to their output is key.

Die ink and the curing system are the heart of the UV-drukwerk proses. UV ink isn’t like typical solvent or aqueous inks. It’s a monomer/oligomer mixture with photoinitiators. When exposed to the correct wavelength of UV-lig, these photoinitiators trigger polymerization, rapidly turning the liquid ink into a solid, durable layer.

Key aspects of UV ink sluit in:

Die UV LED curing system is equally critical. Modern LED UV systems offer significant advantages over older mercury vapor lamps:

As a manufacturer, we carefully match our uv platbed drukker with optimized ink formulations and state-of-the-art UV LED curing systems, such as those found in our advanced large format UV Hybrid Printer, to ensure reliable performance and excellent adhesion across the widest possible range of applications, from detailed telefoonkas druk to large-scale industriële drukwerk. The synergy between the inkjet system, the UV ink, and the UV-lig source defines the final drukkwaliteit.y combination remains a cornerstone for many businesses due to its rigid media capabilities.

Proper maintenance is crucial for maximizing the lifespan of your UV drukker and ensuring consistent drukkwaliteit. While specific procedures vary by model, some general best practices apply, and reliable manufacturers provide clear guidelines and support.

Daily Checks & Cleaning:

Weekly/Monthly Maintenance:

Preventative Maintenance:

As 'n UV Flatbed Printer Manufacturing plant, we design our machines for ease of maintenance and provide comprehensive manuals, video tutorials, and technical support. We understand that minimizing downtime is critical for your print business. Our service contracts often include preventative maintenance visits by certified technicians, ensuring your UV flatbed printing machine of digital uv flatbed printer runs optimally for years to come. Think of regular maintenance as protecting your valuable druk toerusting investment.

What makes UV printing different from solvent printing?

UV-drukwerk gebruike UV ink that is cured instantly by UV-lig, allowing printing on a wider variety of materials (especially rigid ones) with sharper details and no drying time. Solvent printing uses inks that evaporate solvents to dry, often requiring specific coated media and releasing more VOCs. UV-drukwerk is generally faster for finishing and more environmentally friendly.

How durable are prints made with a UV printer?

UV ink forms a hard, cross-linked layer upon curing, making prints quite durable and resistant to scratches, abrasion, water, and fading from sunlight. Durability varies based on the specific ink formulation, substrate, and environmental exposure, but it’s generally considered excellent for signage, industrial marking, and promosie produkte. Adding a varnish printing layer can further enhance protection.

Is operating a large format UV flatbed printer difficult?

Moderne UV drukkers come with user-friendly software and automated maintenance features. While there’s a learning curve, reputable manufacturers like us provide comprehensive training covering operation, software (RIP), basic maintenance, and material handling. With proper training, operators can quickly become proficient in managing the digitaal uv druk masjien and achieving high-quality results.

Can UV printers print white ink and varnish?

Yes, many professional UV-vlakbeddrukkers en hibriede drukkers are equipped with channels for both white ink and clear varnish. White ink is essential for printing vibrant colors on dark or transparent substrates (glas drukwerk, akriel). Varnish printing allows for spot gloss, matte finishes, or even textured/embossed effects, adding significant value to prints.

What kind of support can I expect after buying a UV printer from a manufacturer?

As a dedicated UV Flatbed Printer Manufacturing plant, we offer comprehensive support including installation, on-site/remote training, technical phone/email support, readily available spare parts, software updates, and warranty services. Extended service contracts and preventative maintenance plans are often available to ensure maximum uptime and peace of mind for your druk toerusting.

How much space do I need for a UV flatbed printer?

Space requirements vary significantly. A small uv printer like an A3 UV drukker of desktop uv flatbed printer might fit on a large table or require minimal floor space. A groot formaat UV platbed drukker (e.g., 4×8 ft or larger bed size) requires substantial space for the machine itself, plus clearance around it for loading/unloading materials, maintenance access, and ink storage. Always check the manufacturer’s specifications for footprint and recommended operating space.

Partnering with the right UV Flatbed Drukker Vervaardiger is crucial for leveraging the power of this versatile druk tegnologie. Remember these key points:

As a dedicated UV Flatbed Printer Manufacturing plant, we are committed to providing not just cutting-edge drukmasjiene, but also the partnership and support you need to thrive. Our range of UV drukkers, from compact desktop uv models to large format uv flatbed en hybrid uv systems, are designed to meet the demanding needs of businesses like yours.

Ready to explore how our UV printing solutions can elevate your business? Contact us today to discuss your specific drukbehoeftes, request print samples, or schedule a demonstration. Let’s unlock new possibilities together.