Per evitare che la tua richiesta risponda in ritardo, inserisci il tuo WhatsApp/WeChat/Skype insieme al messaggio, così possiamo contattarti al primo tentativo.

Ti risponderemo entro 24 ore. Se per un caso urgente, aggiungi WhatsApp: +8617888313102, o WeChat: +86 17864107808. Oppure chiama +86 17864107808 direttamente.

*Rispettiamo la tua riservatezza e tutte le informazioni sono protette. Utilizzeremo le tue informazioni solo per rispondere alla tua richiesta e non invieremo mai e-mail indesiderate o messaggi promozionali.

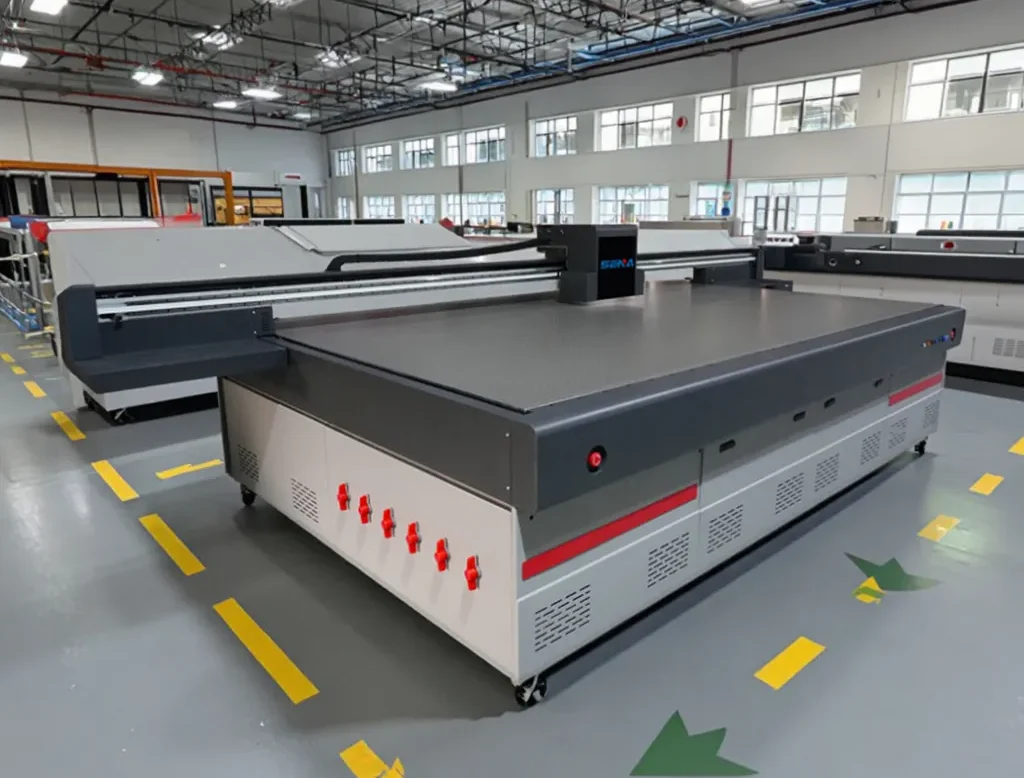

Figure 1: SENA UV flatbed printer demonstrating 3D texture printing on wood panels.

The SENA UV flatbed printer has redefined wood art manufacturing by integrating 3D texture printing technology. Unlike traditional flat printing, this system uses variable ink droplet sizes (5-35pl) and multi-layer varnish printing to create tactile relief effects. Tests show that wood panels printed with 3D textures command a 40% price premium in the home decor market compared to flat designs.

Key components enabling this innovation:

Figure 2: Side-by-side comparison of flat printing (left) vs 3D texture printing (right) on oak panels.

The integrated CCD vision scanning system addresses wood’s inherent material variability. By analyzing surface irregularities at 0.01mm accuracy, it automatically adjusts:

This technology proved critical in a SENA SN-9060 UV flatbed printer trial with a major furniture brand, reducing material waste from 12% to 2.3% while maintaining 98.7% color consistency across batches.

SENA’s proprietary auto-cleaning system extends printer uptime by 40% through:

For wood applications, the system automatically switches to low-viscosity UV ink when detecting surface porosity >15%, ensuring optimal penetration without sacrificing print speed (26m²/hr in quality mode).

While optimized for wood, the SENA UV printer demonstrates exceptional substrate adaptability:

| Materiale | Application Example | Key Requirement |

|---|---|---|

| Custodie per telefono | SENA SN-3045 printing custom designs on TPU | Flexible material compatibility |

| Piastrelle di ceramica | 600×600mm tile printing with gloss varnish | High-temperature resistance (80°C) |

| Metal signs | Outdoor signage with 5-year UV durability | Weatherproof UV ink formulation |

IL SENA SN-1800 flexible material printer extends capabilities to 3D objects like cylindrical bottles, achieving 360° seamless printing through rotary axis integration.

Early adopters report transformative results:

“Our oak wall panels previously sold for $85/m². After introducing SENA’s 3D texture printing, we now charge $119/m² with 92% customer acceptance rate.” – James Wilson, CEO of Artisan Woodworks

Key value drivers:

SENA offers tailored solutions across price/performance spectrum:

| Modello | Area di stampa | Core Feature | Target Application |

|---|---|---|---|

| Codice SN-3045 | 300×450mm | Portable design | Phone case printing |

| Codice SN-9060 | 900×600mm | CCD vision system | Furniture panels |

| Modello SN-2513E | 2500×1300mm | Dual Ricoh GEN6 heads | Stampa di piastrelle in ceramica |

The SENA UV flatbed printer represents a paradigm shift in industrial printing, merging artistic expression with manufacturing precision. By integrating 3D texture capabilities, intelligent material handling, and sustainable UV ink technologies, it creates new value chains across woodworking, consumer electronics, and architectural decor industries. As manufacturers adopt these systems, we anticipate 28% CAGR growth in the high-quality printing equipment market through 2030.